PU Athletic Track Manufacturer (Turnkey Running Track Solutions)

If you are looking for a reliable PU athletic track manufacturer for a school, club, stadium, academy, or commercial sports facility, the most important decision is not only “price”—it’s choosing the right system, using quality-controlled materials, and executing correct sub‑base and installation planning.

At Sport Floor Manufacturer, we support athletics track construction with factory-direct track materials and turnkey project execution—from system selection and base requirements to production, quality control, export packaging, and installation guidance. Our running track systems are designed to meet World Athletics (formerly IAAF) requirements depending on your project specification and intended level of use.

For complete track solutions, visit: Tartan Running Track

———————————————————

Factory‑Direct Track Materials + Turnkey Execution

As a PU running track manufacturer, our goal is to help you build a track that performs well in real conditions (hot climates, high usage, and long-term maintenance) while keeping procurement simple and transparent.

Who we work with

- Sports clubs and stadium owners

- Schools, universities, and academies

- Contractors and developers

- Government and tender-based projects (requirements vary by country)

What we provide (turnkey-ready support)

- System recommendation (Full PU / Sandwich / Spray) based on usage and budget

- Track materials supply (PU binders, primers, topcoats, line marking paint, etc.)

- Technical documentation and installation guidance

- Export packaging and shipping support (EXW / FOB / CIF)

- Optional on-site supervision (project dependent)

A PU Athletic Track is a multi-layer polyurethane running surface engineered for shock absorption, energy return, and durability, widely used in professional stadiums and schools, and compliant with World Athletics standards when properly installed.

Get a Running Track Quote (Fast)

Send your project details to receive a clear quotation:

- Country/City (or nearest port)

- Number of lanes

- System type (Full PU / Sandwich / Spray)

- Indoor or outdoor

- Scope (materials only or turnkey)

- Incoterms (EXW / FOB / CIF)

- Target timeline

Start your request here: Tartan Running Track

PU sports flooring manufacturer

As a PU sports flooring manufacturer, not a trading company, Sport Floor Manufacturer designs, produces, and controls every component of the PU athletic track system—from binders to surface performance—ensuring consistent quality worldwide.

What Is a PU Athletic Track?

A PU (Polyurethane) athletic track is a seamless, high-performance synthetic running surface engineered to deliver controlled shock absorption, high energy return, and long-term durability in all climates. Built with multiple PU layers combined with calibrated rubber granules, it provides consistent athlete safety, faster performance, and optimized lifecycle cost. When properly designed and installed, PU athletic tracks meet World Athletics performance standards, making them suitable for professional stadiums and educational facilities.

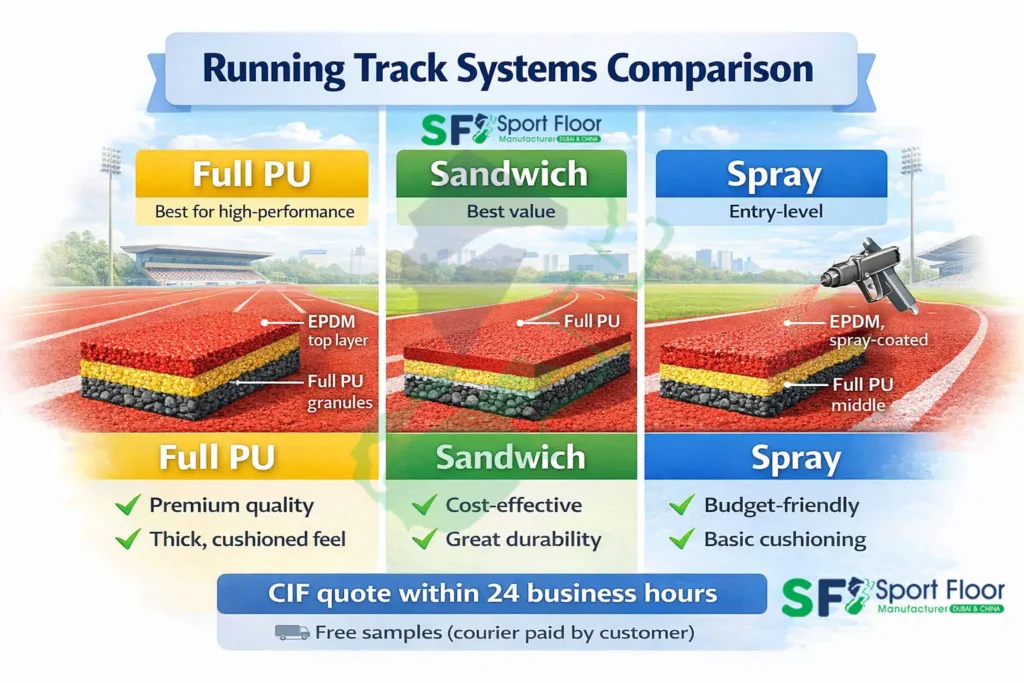

Track Systems We Deliver (Full PU / Sandwich / Spray) + Quick Comparison

Different projects require different performance and budget levels. Below is a practical comparison of the main systems we deliver. For the full breakdown, see: Running Track Systems (Full PU vs Sandwich vs Spray)

Quick comparison (simple and practical)

Full PU running track

- Best for: professional use, high-traffic facilities, premium performance needs

- Advantages: uniform performance, high durability, premium finish options

- Notes: requires strong sub-base quality and controlled installation

Sandwich running track

- Best for: clubs, schools, and multi-sport facilities needing strong value

- Advantages: excellent cost-to-performance ratio, strong wear resistance

- Notes: widely selected for budget + durability balance

Spray coat running track

- Best for: entry-level budgets, training facilities, controlled usage

- Advantages: lower cost, faster execution when site is ready

- Notes: best when correctly matched to usage expectations

Not sure which system fits your budget?

Our team will recommend the right Full PU / Sandwich / Spray coat running track specification for your climate, usage level, and maintenance plan—so you avoid overpaying or underbuilding.

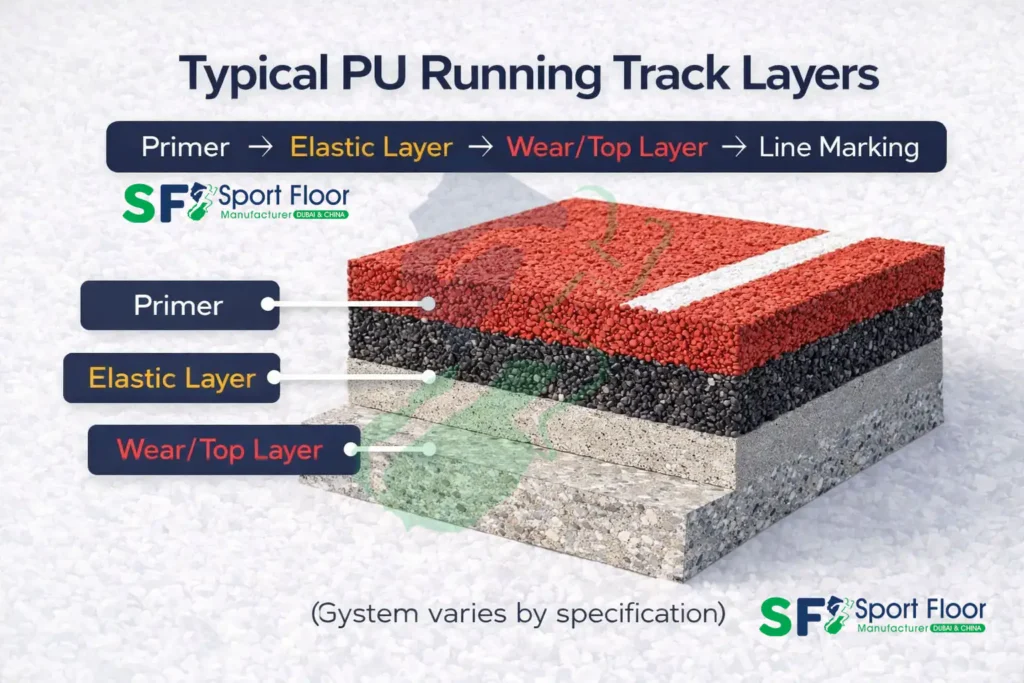

Technical Specifications (Thickness, Layers, Slip Resistance, Drainage, Line Marking)

A professional running track is not “one material.” It is a layered system built on a correct base. The final specification depends on usage level (school vs club vs stadium), climate, and project requirements.

Typical system elements (may vary by design)

- Primer: improves bonding to the base

- Elastic layer: contributes to shock absorption and athlete comfort

- Wear/top layer: texture and durability for performance and safety

- Line marking: accurate layout for lanes, starts, and competition markings

Performance and safety considerations

- Slip resistance: surface texture must match usage and weather exposure

- Drainage planning: critical for outdoor tracks (base slope and water management)

- UV exposure: outdoor materials must be suitable for long sun exposure

- Maintenance plan: easier cleaning and long-term surface stability

For track-related materials and components, see: Tartan Materials

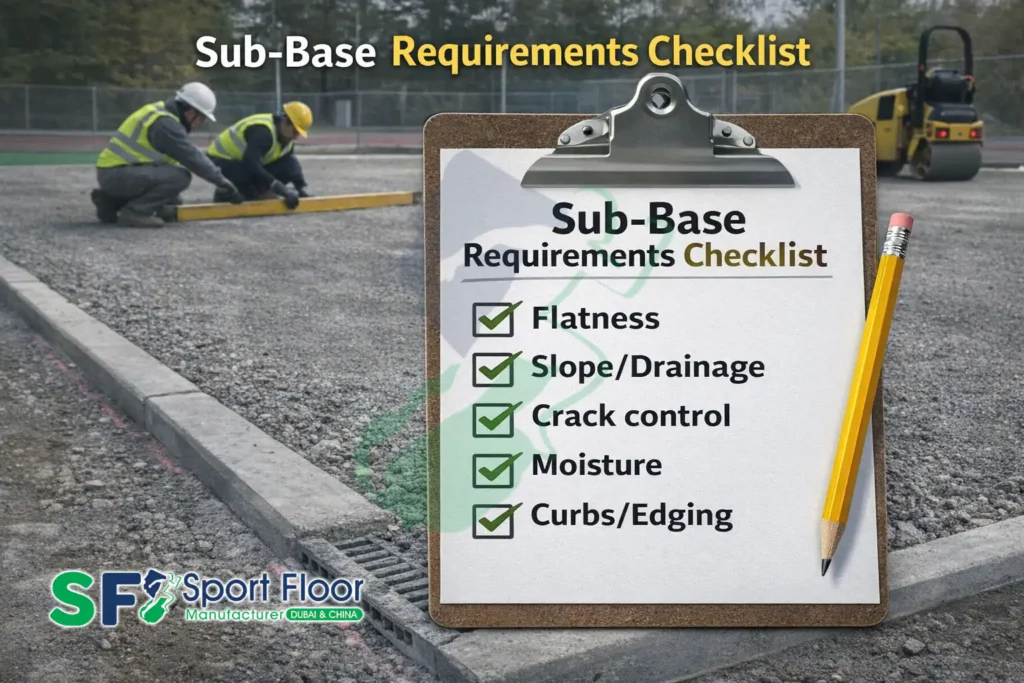

Sub‑Base & Civil Works Requirements (Quick Checklist)

Most running track problems come from the sub-base (civil works), not the top surface. Before installation, confirm:

- Base type: asphalt or concrete (as specified)

- Flatness & tolerance: consistent leveling to avoid thickness variations

- Slope & drainage: correct slope for outdoor water drainage

- Crack control: base must be stable and properly treated

- Moisture control: ensure base readiness before applying PU layers

- Curbs & edging: correct dimensions and alignment

- Electrical planning: lighting and nearby facility connections (if required)

If your project includes courts or a multi-use facility, review: PU Sports Flooring

Quality Control, Documentation & Compliance

To support professional procurement, we provide:

- Quality checks during material preparation and packing

- Batch labeling for traceability (project dependent)

- TDS/SDS available upon request for key materials

- Installation guidance to support correct on-site application

For facilities that also require rubber surfacing materials (playgrounds, sports zones, etc.), we supply: EPDM Granules Supplier & Manufacturer

If you need help selecting EPDM sizes, use: EPDM Granules Sizes Guide

PU Athletic Track Systems

1. Full PU Athletic Track System

System Description

A seamless, rubber-free surface built entirely with polyurethane layers.

System Structure

PU Primer

Self-Leveling Elastic PU Layer

PU Leveling Layer

Aliphatic PU Textured Top Coat

Key Benefits

Seamless and uniform finish

Excellent shock absorption

Very high abrasion resistance

Premium aesthetic appearance

Best For

Indoor athletic tracks

High-end sports facilities

Multi-purpose indoor arenas

2. PU Sandwich Athletic Track System

System Description

The most widely used PU Running track system worldwide.

System Structure

PU Primer

Elastic Layer (PU Binder + SBR Granules)

PU Leveling Layer

EPDM Rubber Wearing Course

Key Benefits

Balanced performance and durability

Excellent slip resistance

Strong UV and weather resistance

Proven long-term reliability

Best For

Outdoor stadiums

Schools and universities

Training and competition tracks

3. PU Spray-Coat Athletic Track System

System Description

A cost-effective PU athletic track solution for large outdoor areas.

System Structure

PU Primer

Elastic Layer (PU Binder + SBR Granules)

Spray-Applied PU Binder + EPDM Granules

Key Benefits

Fast installation

High surface traction

Economical for large projects

Best For

Public athletics facilities

Training tracks

Community sports complexes

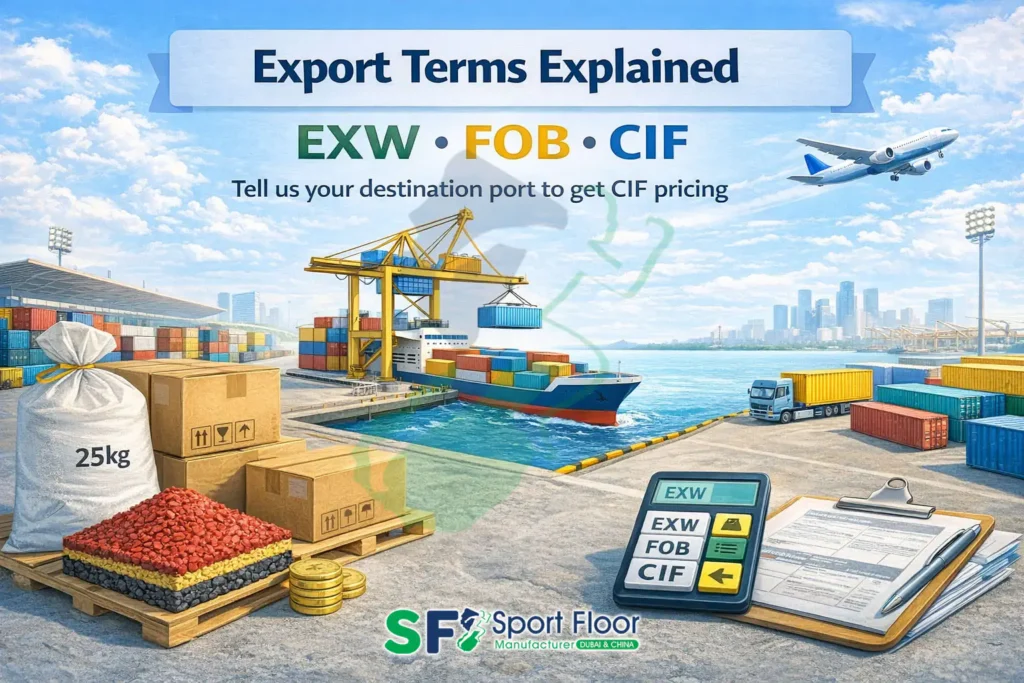

Export & Delivery Terms (EXW / FOB / CIF) + Lead Time

We support international projects with export-ready packaging and shipment planning based on your preferred Incoterms:

- EXW (Ex-Works): collection from our supply point according to agreement

- FOB: delivery to export port and loading (as agreed)

- CIF: shipping to your destination port (freight terms depend on route and timing)

Lead time: depends on system type, order scope, and project schedule. Once you share your lane count, system selection, and destination, we confirm a clear supply and delivery plan.

For a full overview of selection logic, refer to: Running Track Systems

Common PU Athletic Track Problems — And Our Solutions

Problem 1: Premature surface failure

Cause: Low-quality PU binders or incorrect curing

Solution: Manufacturer-formulated PU with controlled chemistry

Problem 2: Uneven athlete performance

Cause: Inconsistent layer thickness

Solution: System-defined thickness and on-site supervision

Problem 3: High maintenance cost

Cause: Weak wear layers

Solution: Abrasion-resistant top courses

Problem 4: Certification rejection

Cause: Poor system design

Solution: Certification-ready PU Running track systems

Installation: Where PU Athletic Tracks Succeed or Fail

Installation is a technical operation, not manual labor.

Our installation methodology includes:

Substrate testing and correction

Moisture and adhesion control

Precise material mixing ratios

Controlled curing times

Environmental monitoring

Post-installation inspection

This ensures the installed PU athletic track performs exactly as engineered.

Maintenance & Lifecycle Value of PU Athletic ( Running) Tracks

A professionally manufactured PU athletic Running track offers:

15–20 years expected service life

Low routine maintenance

Periodic line repainting

Localized repairs instead of full replacement

This dramatically reduces total cost of ownership.

Sustainability in PU Athletic Track Systems

Sustainability is achieved through engineering longevity, not labels.

Our PU athletic track systems support sustainability via:

Long service life

Optional recycled EPDM content

Low-VOC PU formulations

Reduced resurfacing frequency

Request a Quote (What to Send for the Fastest Reply)

To receive an accurate quotation for your athletics track construction, send:

- Country + city (or destination port for CIF quotes)

- Number of lanes (and straight length if applicable)

- System type: Full PU / Sandwich / Spray coat

- Indoor or outdoor + climate notes (hot/coastal/high humidity)

- Base status: ready sub-base or civil works required

- Scope: material supply only or turnkey project support

- Incoterms: EXW / FOB / CIF

- Target timeline

What you will receive:

- System recommendation (if needed)

- Technical scope and key requirements

- Lead time confirmation

- Clear commercial offer aligned with your Incoterms

Request now: Tartan Running Track

FAQ — PU Athletic Track Manufacturer

1) Are you a PU athletic track manufacturer or only a contractor?

Sport Floor Manufacturer supports projects with factory-direct track materials and turnkey execution planning. Depending on your scope and location, we can supply materials, provide installation guidance, and support turnkey implementation.

2) Which running track system should I choose: Full PU, Sandwich, or Spray?

The right choice depends on usage intensity, budget, climate, and sub-base readiness. Compare systems here: Running Track Systems (Full PU vs Sandwich vs Spray)

3) Do you deliver tracks designed to meet World Athletics (IAAF) requirements?

We deliver track systems designed to meet World Athletics requirements depending on the approved project specification and installation method. If you have tender requirements, send them and we will confirm what can be provided.

4) Do you support export shipping terms (EXW/FOB/CIF)?

Yes. We support EXW, FOB, and CIF shipments based on your procurement preference and destination.

5) What documents can you provide?

TDS (Technical Data Sheets) and SDS (Safety Data Sheets) are available upon request for key materials. Additional documentation depends on market requirements and project scope.

6) Can you supply EPDM materials for related sports surfaces?

Yes. We supply EPDM granules and can confirm size selection using the EPDM granules sizes guide.

7) Do you support multi-sport facilities beyond running tracks?

Yes. For court areas and multi-use zones, explore: PU Sports Flooring

8) What information do you need to quote quickly?

Country/city (or port), lane count, system type, indoor/outdoor, base status, scope (supply only or turnkey), and Incoterms (EXW/FOB/CIF).

Next Step

For a complete overview of components, visit Tartan Materials, then request your quotation from Tartan Running Track.

Why Global Clients Choose Sport Floor Manufacturer

Manufacturer, not trader

In-house PU chemistry

Proven system designs

Transparent technical documentation

Climate-adapted formulations

International project experience

We compete on lowest risk and highest lifecycle value.

Unlike resellers, Sport Floor Manufacturer controls PU formulation, layer thickness, and system performance—ensuring predictable results and long-term value.

What Is the Relationship Between PU Sports Flooring and Running Track Systems?

PU Sports Flooring is the core technology behind professional Running Track Systems. While running track systems define the overall structure, thickness, and installation method, PU sports flooring delivers the elastic performance, shock absorption, and energy return that athletes rely on.

At Sport Floor Manufacturer, we engineer both as one integrated solution. This eliminates compatibility issues, ensures consistent performance across the entire track, and significantly reduces long-term maintenance costs.

Choosing a manufacturer that controls both the PU flooring formulation and the running track system design is the only way to guarantee safety, durability, and international compliance.

Discover how our PU Sports Flooring and Running Track Systems work together to build high-performance athletic tracks.

PU Athletic – Running Track vs. Acrylic Track Systems – Technical Comparison

| Comparison Factor | PU Running Track (Polyurethane) | Acrylic Track System |

|---|---|---|

| System Type | Multi-layer elastic synthetic system | Thin rigid surface coating |

| Shock Absorption | High (20–35%) – protects joints and muscles | Very Low (0–5%) – minimal impact protection |

| Energy Return | Excellent – enhances speed and performance | Limited – surface is hard and non-elastic |

| Athlete Safety | Designed to reduce injury risk | Higher injury risk due to hardness |

| Surface Comfort | Elastic, resilient, and fatigue-reducing | Hard, similar to painted asphalt |

| Durability | 15–20 years with proper installation | 5–8 years depending on traffic |

| Weather Resistance | UV, heat, cold, and moisture resistant | UV resistant but sensitive to cracking |

| Crack Resistance | High elasticity prevents cracking | Cracks with substrate movement |

| All-Weather Performance | Excellent grip in wet and dry conditions | Slippery when wet |

| Spike Resistance | Fully spike-compatible | Not recommended for spikes |

| Maintenance Cost | Low, predictable lifecycle cost | Frequent repainting required |

| Installation Complexity | Technical installation by trained teams | Simple coating application |

| Certification Capability | Suitable for World Athletics standards | Not eligible for certification |

| Customization Options | Colors, textures, thickness control | Limited color options only |

| Typical Applications | Stadiums, universities, schools, clubs | Jogging paths, playgrounds |

| Initial Cost | Higher upfront investment | Lower initial cost |

| Total Cost of Ownership | Lower over lifecycle | Higher due to frequent repairs |

| Performance Level | Professional & competition-grade | Recreational only |

Summary for Buyers (Conversion-Oriented)

If your priority is athlete safety, performance, durability, and certification, a PU Athletic – Running Track is the correct system-level solution. While acrylic tracks appear cost-effective initially, their lack of elasticity results in higher injury risk, shorter lifespan, and increased long-term maintenance costs.

For facilities aiming to meet professional, educational, or competitive standards, PU systems deliver higher return on investment and long-term operational reliability.

If your facility includes indoor or multi‑purpose courts, explore our PU sports flooring solutions as well

Frequently Asked Questions About PU Athletic Track

What is a PU athletic track?

A synthetic athletics surface engineered with polyurethane binders to deliver controlled elasticity, traction, and durability.

How long does a PU Running track last?

Typically 15–20 years with correct installation and maintenance.

Can PU Running tracks be certified?

Yes, when designed and installed according to international standards.

Is PU safe for athletes?

Yes. Properly engineered PU tracks reduce joint stress and injury risk.

Final Thought: PU Athletic Track Is an Engineered Investment

A PU athletic track is not a surface — it is a precision sports system.

At Sport Floor Manufacturer, we engineer PU Running tracks using

material science, manufacturing control, and field experience to deliver predictable performance worldwide.

Call to Action: Request Your PU Running Track Proposal

If you are planning a new athletic facility or upgrading an existing track, contact Sport Floor Manufacturer for:

PU athletic (Running) track system recommendation

Technical specifications

Budget estimation

Installation timeline

Build your athletic track with a manufacturer — not a middleman.

Conclusion

Choosing the right running track is not only about selecting a system—it’s about matching the correct Full PU, Sandwich, or Spray specification to your usage level, climate, and sub‑base conditions, then executing the project with clear technical requirements and reliable supply.

As your PU athletic track manufacturer, Sport Floor Manufacturer supports you with system recommendation, factory-direct materials, export-ready logistics (EXW/FOB/CIF), and documentation (TDS/SDS upon request) so you can plan your project with confidence and avoid costly mistakes.

If you’re ready to move forward, send your country/city (or destination port), number of lanes, preferred system, and project timeline and request a quotation here:

Contact Our Technical Sales Team

📧 Cairo: Cairo@sportfloor-m.com

📧 China: China@sportfloor-m.com

🔗 Request Form: Contact Us – Sport Floor Manufacturer