Poured Rubber Flooring (Wet Pour) (2026 Guide): Materials, EPDM Granules, Binder Basics & Export Procurement

Poured rubber flooring (also known as wet pour rubber flooring, poured-in-place rubber flooring, or wet pour rubber surfacing) is one of the most reliable surfacing options for playgrounds and sports recreational areas because it combines safety, drainage, design flexibility, and long-term outdoor performance—when the correct materials and specifications are used.

This guide explains how wet pour systems work, what to specify (granules, binder, thickness, and packaging), and how to request an accurate export quotation without mismatched offers.

If you’re sourcing granules for an active project, start here: EPDM Granules Supplier

Or contact our team directly: contact us

Wet Pour Rubber Flooring vs Poured-in-Place Rubber Flooring (Terminology)

“Both terms are commonly used in the market and refer to the same wet pour surfacing approach, depending on region and industry usage.”

Table of Contents

- What Is Poured Rubber Flooring (Wet Pour)?

- Where Wet Pour Rubber Flooring Is Used

- Typical Wet Pour System Structure (Base + Wear Layer)

- EPDM Granules: What to Specify (Sizes, Colors, Batch Consistency)

- Binder Basics (What Buyers Should Confirm)

- Common Installation Problems (and How to Prevent Them)

- Export Packaging, Lead Time & Procurement Checklist

- EXW vs FOB vs CIF: Getting the Right Quote

- Proof & Trust: Samples, Photos, Documents

- FAQ — Poured Rubber Flooring

1) What Is Poured Rubber Flooring (Wet Pour)?

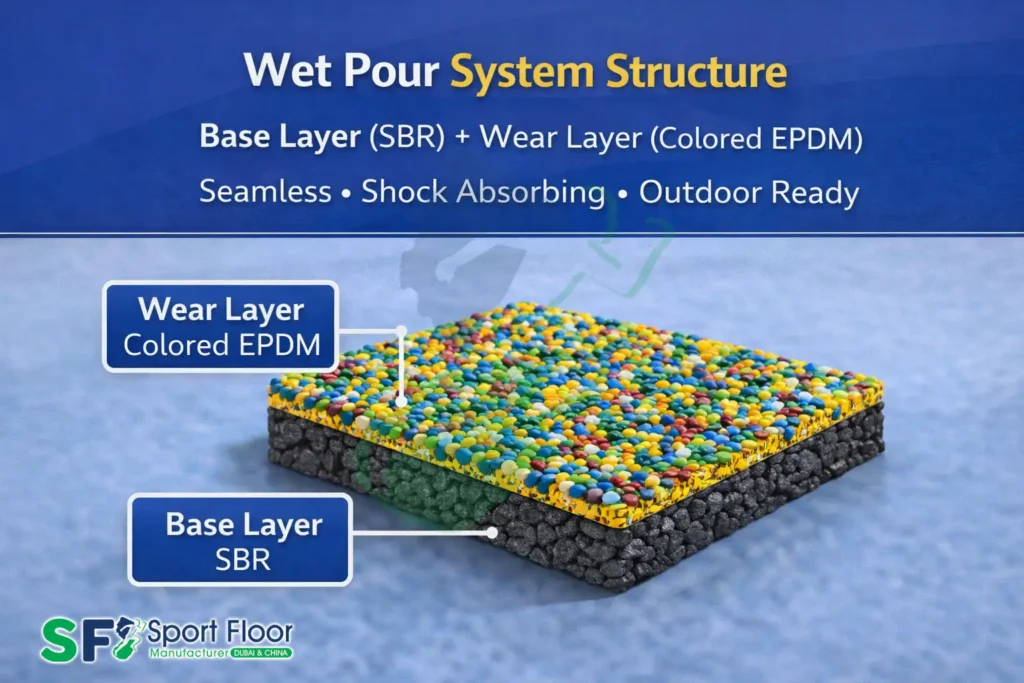

Poured rubber flooring is a seamless rubber surface created by mixing rubber granules with a polyurethane binder and applying the mixture on-site. The surface is typically installed as a two-layer system:

- a shock-absorbing base layer (often SBR/black rubber granules), and

- a colored top layer (commonly EPDM granules) that provides appearance and outdoor durability.

Because it is poured in place, the system can be customized for:

- thickness (safety performance),

- colors and patterns (design zones, logos),

- surface texture (fine vs coarse finish).

If you want a general overview of EPDM granules (definitions, uses, and key quality factors), visit:

EPDM Granules (Guide/Hub)

2) Where Wet Pour Rubber Flooring Is Used

Wet pour systems are common in projects where safety + durability + visual finish are required:

Playgrounds & Poured-in-Place Safety Surfacing

A major advantage of poured rubber flooring for playgrounds is the ability to design:

- multi-color play zones,

- paths and shapes,

- branding elements for schools, parks, or municipalities.

Sports & Recreational Rubber Areas

Wet pour is also used for:

- recreation spaces and outdoor activity zones,

- club/community facilities,

- walkways and public garden recreation surfaces (project dependent).

If your project is a full sports complex (tracks/courts), you may also review:

3) Typical Wet Pour System Structure (Base + Wear Layer)

A professional wet pour system is usually specified by layers (not by “rubber flooring” as one material).

Layer A: Base Layer (Shock Absorption)

- Often uses black rubber granules (commonly SBR).

- Designed to provide cushioning and support under impact.

If your project requires SBR/crumb rubber, see:

Rubber Granules (SBR)

Layer B: Wear Layer (Appearance + Outdoor Performance)

- Commonly uses colored EPDM granules.

- This is the visible layer, so color consistency and UV performance matter most here.

4) EPDM Granules: What to Specify (Sizes, Colors, Batch Consistency)

Many wet pour problems start with vague purchasing specs. For best results, specify EPDM granules by:

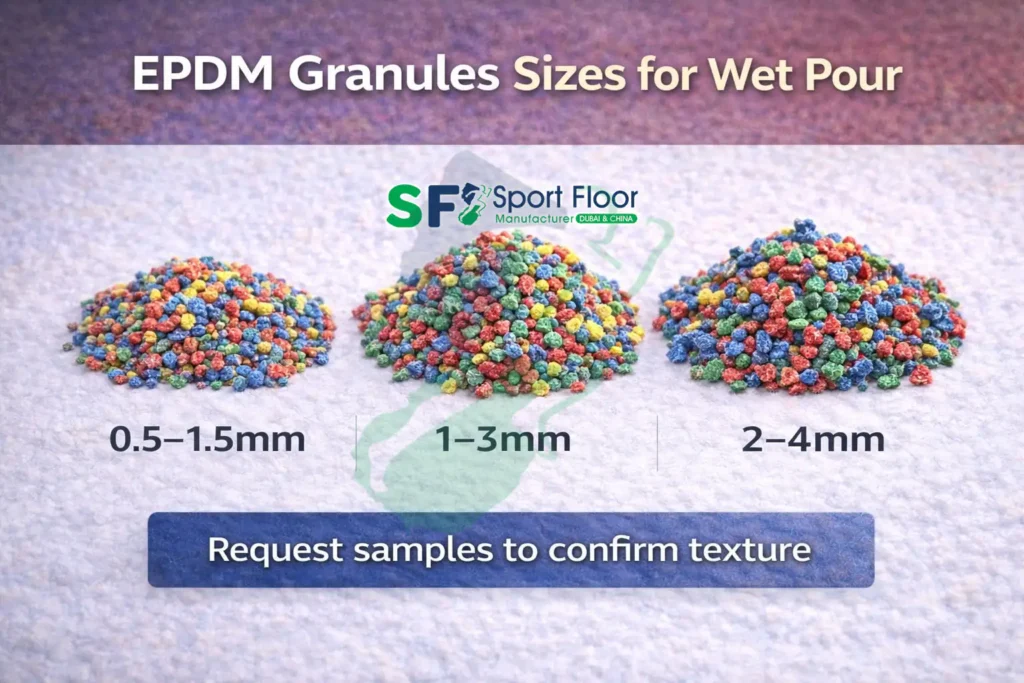

A) Granule Size (Surface Texture + Visual Finish)

The most requested EPDM granules sizes for wet pour projects include:

- 0.5–1.5mm (fine finish / refined look)

- 1–3mm (very common for wet pour wear layers)

- 2–4mm (more texture / stronger granule definition)

Full guide (with practical selection rules):

EPDM granules sizes guide

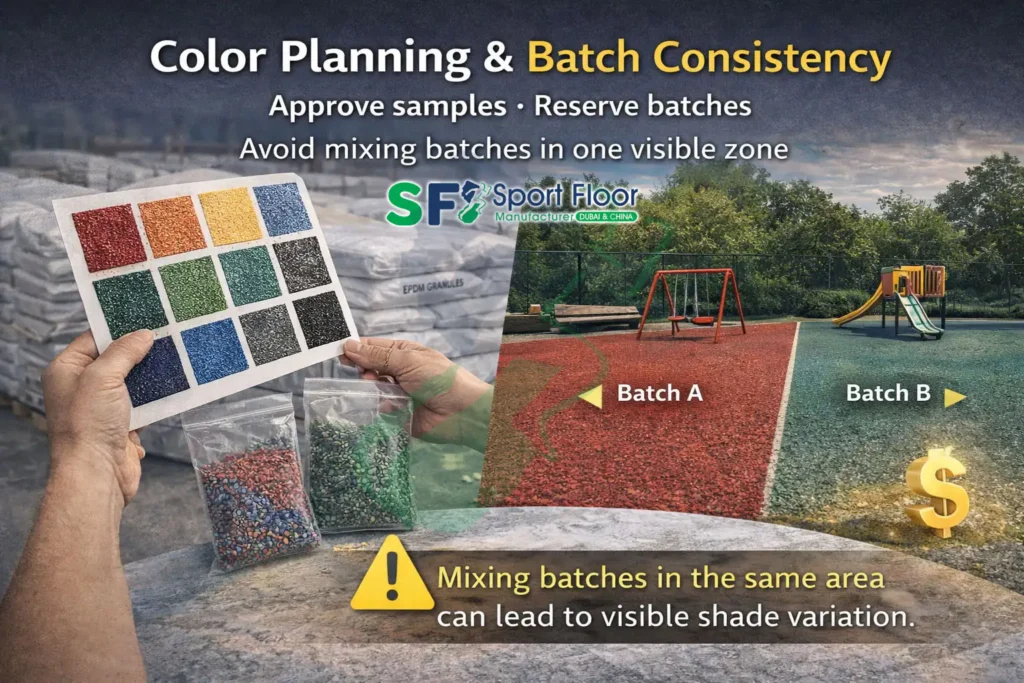

B) Color Selection (Single Color vs Blends)

Standard colors and custom mixes are used depending on project design. For professional projects, always confirm:

- a color chart (what is actually available),

- physical samples (shade under sunlight),

- batch planning if the project is installed in phases.

Full guide (colors + blends + shade variation control):

EPDM granules colors

C) Batch Consistency (Critical for Large/Phased Projects)

If a project is installed in phases, small shade differences between batches become visible—especially in bright colors and large areas. Best practice:

- order full quantity early (or reserve batches),

- approve samples from the intended batch,

- avoid mixing batches in one visible zone.

D) Pricing Factors (No “One Price Per Ton”)

Wet pour buyers often compare offers incorrectly. EPDM granules pricing changes based on:

- size range,

- color/blend complexity,

- order volume (tons),

- packaging,

- EXW/FOB/CIF and destination port.

Pricing explanation:

EPDM granules price per ton (EXW/FOB/CIF)

Wholesale planning (MOQ, packaging, lead time):

EPDM granules wholesale

5) Binder Basics (What Buyers Should Confirm)

In wet pour rubber flooring, binder selection and handling often matter as much as the granules.

Buyers typically need to confirm:

- binder suitability for outdoor wet pour systems,

- workability and curing behavior under local climate conditions,

- installer method and mixing discipline.

Important note: final binder choice and mixing ratio should follow your system design and installer method. If you want a faster, more accurate quotation, always tell your supplier the application (playground / sports surfacing) and your climate/region.

6) Common Installation Problems (and How to Prevent Them)

Here are frequent problems buyers face—and what should be confirmed before ordering materials:

Problem 1: Uneven Finish / Wrong Texture

Often caused by:

- incorrect granule size selection,

- inconsistent grading,

- mixing or application issues.

Prevention:

- choose size based on finish goal,

- approve samples in the exact size + color combination.

Problem 2: Shade Variation Between Areas

Often caused by:

- ordering in phases without batch planning,

- mixing batches in one area.

Prevention:

- reserve batches for phased installations,

- keep batch labeling and separation on-site.

Problem 3: Weak Bonding / Delamination

Often caused by:

- binder mismatch or poor handling,

- poor substrate preparation.

Prevention:

- confirm system compatibility,

- keep storage/handling controlled,

- follow installer best practices.

7) Export Packaging, Lead Time & Procurement Checklist

For global buyers, wet pour procurement is not only “choose material”—it is also logistics.

Packaging Options

Sport Floor supports export-ready packaging for EPDM granules:

- 25kg bags (practical for job sites and distribution)

- Jumbo bags (efficient for large projects with unloading equipment)

Lead Time (What Controls It)

Lead time depends on:

- size,

- colors/blends,

- quantity,

- packaging plan,

- export schedule and destination.

For bulk orders, wholesale details are here:

epdm granules wholesale

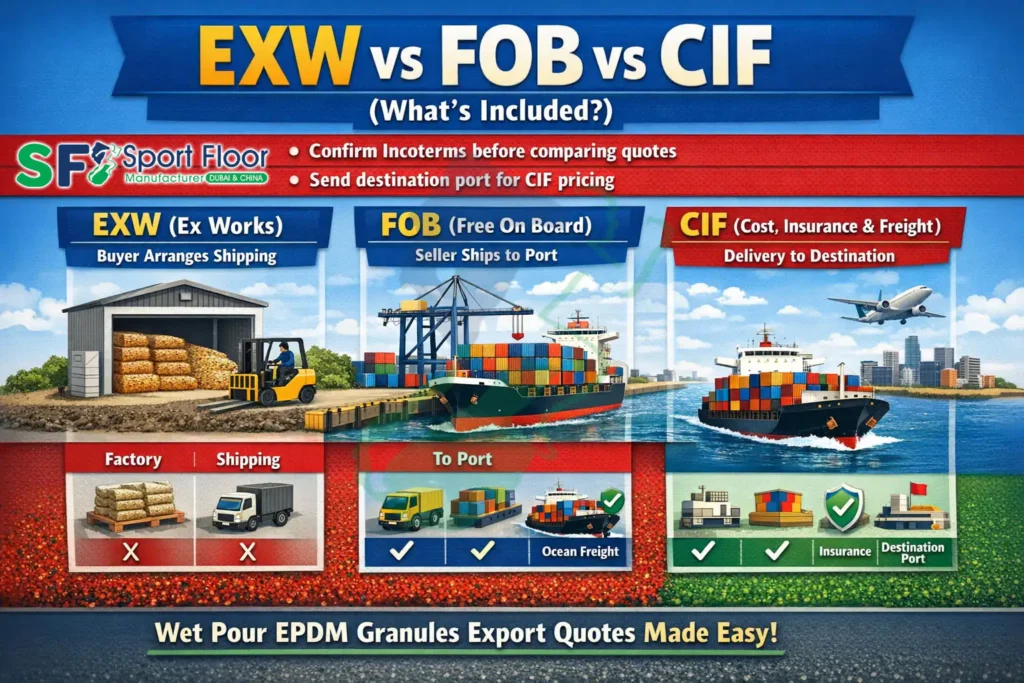

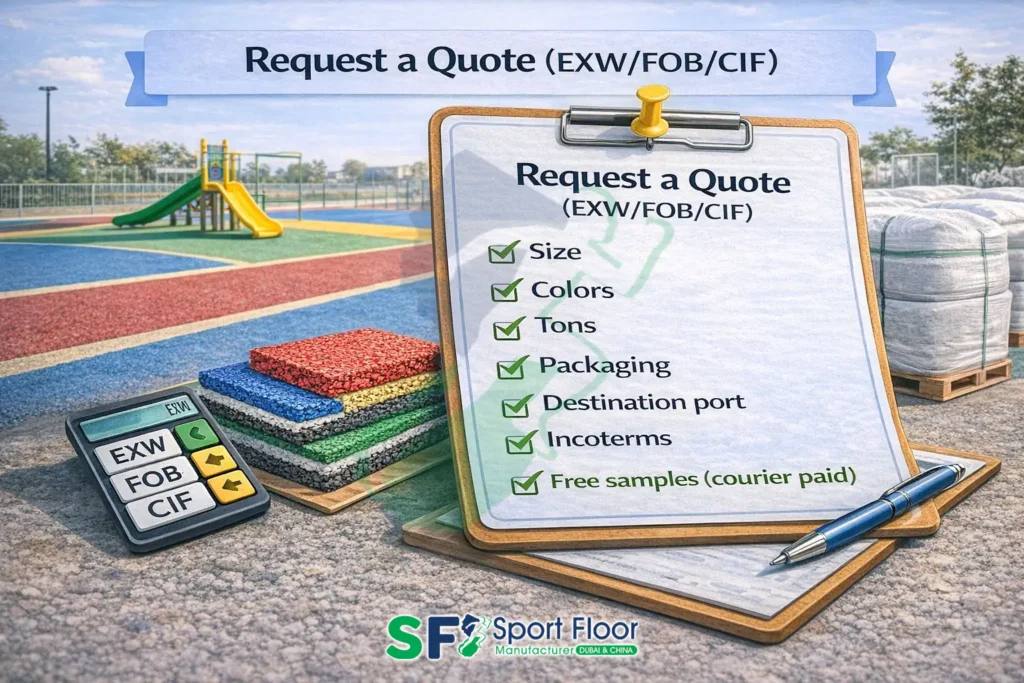

8) EXW vs FOB vs CIF: Getting the Right Quote (Without Mismatched Offers)

When requesting pricing for wet pour materials, always confirm your Incoterms:

- EXW: price at the supply point

- FOB: delivered to export port + loading (as agreed)

- CIF: includes sea freight to your destination port (recommended for budgeting)

If you want the fastest accurate quotation, send:

- size (0.5–1.5 / 1–3 / 2–4mm),

- colors,

- tons,

- packaging (25kg/jumbo),

- destination port,

- Incoterms (EXW/FOB/CIF).

Request pricing via:

EPDM granules supplier

Contact us

9) Proof & Trust: Samples, Photos, Documents

We can support with:

- product photos (granules close-up, blends),

- packaging photos (25kg/jumbo),

- container loading photos (export shipments),

- TDS/SDS available upon request.

Compliance requirements vary by market. For general reference:

You can also review our delivered work here:

Our Projects

Free Samples

Free EPDM granules samples are available for size and color verification (customer pays courier shipping cost only).

Request a Quote (Wet Pour / Poured Rubber Flooring)

Need poured rubber flooring materials for export?

Send your project details and we will reply with a clear quotation and availability confirmation:

- Application (playground / sports surfacing)

- EPDM size (0.5–1.5 / 1–3 / 2–4mm)

- Color(s) and whether you need blends

- Quantity (tons)

- Packaging (25kg or jumbo)

- Destination port + Incoterms (EXW/FOB/CIF)

- Target delivery date

Contact Us

Or start with EPDM supply details here:

FAQ — Poured Rubber Flooring (Wet Pour)

1) What is poured rubber flooring used for?

It’s commonly used for playground safety surfacing and outdoor recreational rubber areas where a seamless, shock-absorbing, design-friendly surface is required.

2) Which EPDM granule size is most common for wet pour top layers?

Many projects use EPDM granules 1–3mm for the wear layer because it provides a balanced finish. The best size depends on the desired texture and system design. See size details here:

epdm granules sizes guide

3) Do colors affect procurement and pricing?

Yes. Color selection (standard vs blends), batch planning, and project phasing can affect quotation and lead time. See the color guide:

epdm granules colors

4) How do I get an export quote for wet pour rubber flooring materials?

Send size, colors, tons, packaging, destination port, and Incoterms (EXW/FOB/CIF). Start here:

epdm granules supplier

Or contact us

5) Can I order wholesale quantities?

Yes—wholesale supply depends on size, color, and packaging. See:

epdm granules wholesale

Conclusion

Poured rubber flooring (wet pour) succeeds when the procurement is precise: correct EPDM granule size, confirmed colors and batches, export-ready packaging, and a quotation based on the right shipping term (EXW/FOB/CIF). If you want a consistent result and a smoother purchasing process, request samples and send your full specification to receive an accurate export offer.

Get started:epdm granules

Contact us

Request Pricing & Free Samples (EXW / FOB / CIF)

To receive an accurate export quotation for your project, send your required size (0.5–1.5 / 1–3 / 2–4mm), color(s), quantity (tons), packaging (25kg/jumbo), and destination port. Our technical sales team will reply with availability, lead time, and shipping terms.

Contact our Technical Sales Team

- 📧 Cairo: Cairo@sportfloor-m.com

- 📧 China: China@sportfloor-m.com

- 📞 WhatsApp: +201204166266

- 🔗 Contact Form: https://sportfloor-m.com/en/contact-us/