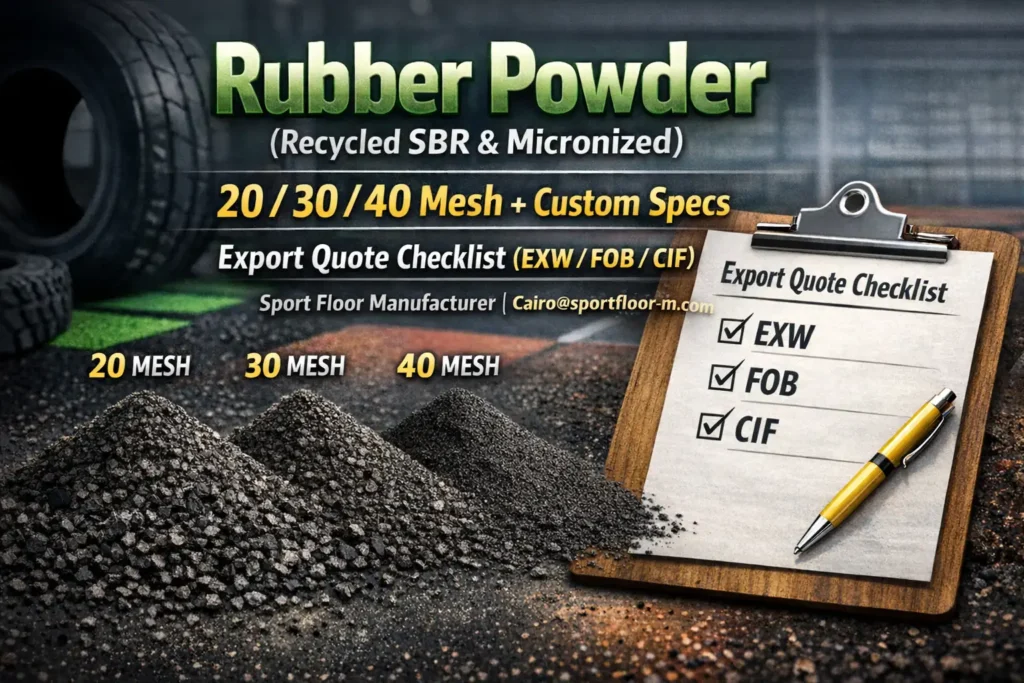

Rubber Powder (Recycled SBR & Micronized) — Mesh Sizes, Uses & Export Supply

Rubber Powder — Fine Rubber Input (Mesh / Spec Dependent)

Sport Floor Manufacturer supplies rubber powder for buyers who need a fine rubber input for flooring-related production and material systems (application-dependent). Export quotation is prepared per ton based on mesh size, cleanliness requirements, packaging, and destination/Incoterms.

Rubber powder is selected when the application requires a finer rubber material than granules. For accurate buying, specify the required mesh size, target use, and tonnage—because powder grades are not interchangeable across all projects.

- Projects requiring fine rubber input (spec-dependent)

- Rubber flooring-related manufacturing and blends (project-dependent)

- Procurement teams comparing suppliers by mesh + packaging + Incoterms

Related Rubber Materials & Buyer Resources

- Granules: SBR Rubber Granules · EPDM Granules

- Binder (system): PU Binder

- Rubber products: Rubber Tiles · Rubber Rolls

- Buyer Guide: Tiles vs Rolls

- Supplier article: Rubber Powder Supplier

Quote Checklist + Incoterms (Rubber Powder)

- Required mesh size: (specify)

- Target application: (specify)

- Total quantity: ton(s)

- Packaging: bag size / pallet preference

- Destination + Incoterms: EXW / FOB / CIF

Official Incoterms reference (ICC): incoterms rules

Rubber powder is recycled rubber processed into controlled particle sizes (mesh grades) for industrial applications such as modified asphalt, coatings, rubber compounds, and engineered mixes.

At Sport Floor, we manufacture and export recycled SBR rubber powder and micronized rubber powder, with standard grades such as 20 / 30 / 40 mesh and custom specifications on request.

Fast quotation: send your required mesh size, application, quantity (tons), destination port, and Incoterms (EXW/FOB/CIF).

Contact form: contact us

Email: cairo@sportfloor-m.com

Key Takeaways (For Buyers)

Recycled rubber powder is specification-based: mesh size, cleanliness requirements, and application determine the correct grade.

We supply recycled SBR rubber powder and micronized rubber powder for different performance needs (application dependent).

Standard grades: 20 / 30 / 40 mesh (custom mesh sizes available on request).

Accurate quotations require matching the same scope: mesh + tons + packing + Incoterms + destination port.

If you need larger particle sizes (granules), that is a different product category (see rubber granules).

For best purchasing results, confirm whether your use case requires standard mesh or micronized grades.

What Is Rubber Powder Used For?

If you searched “what is rubber powder used for”,

here are the most common industrial uses (scope depends on your formulation and local specifications):

- Modified asphalt (rubberized asphalt)

Helps improve durability and cracking resistance (project dependent).

What to confirm: mesh size, dosage guidance, and local road spec requirements. - Coatings & paints

Often uses finer grades where better blending is needed (spec dependent).

What to confirm: micronized vs standard mesh, and compatibility with your formulation. - Rubber compounds & molded products

Used as a filler/additive depending on formulation.

What to confirm: particle size consistency for repeat orders. - Engineered blends / construction mixes

Used in certain mixes where impact absorption and vibration reduction are needed (system dependent).

What to confirm: required mesh, cleanliness, and packing for your process.

If you need rubber granules (SBR) (larger size) instead of powder, see our dedicated page.

If your application is sports flooring systems (tiles/rolls), see rubber flooring.

Rubber Powder: Properties, Types, and Advanced Manufacturing Process

Rubber powder is known for its wide range of physical and chemical properties that make it a highly desirable material in numerous industrial applications. At Sport Floor Rubber Flooring Factory, we ensure that our rubber powder meets the highest standards of purity, strength, and quality.

⦁ Flexibility and Shock Absorption:

Rubber powder provides exceptional elasticity and excellent shock and vibration absorption. This makes it ideal for use in flexible materials, linings, and construction, reducing injury risks on sports surfaces and extending the lifespan of industrial components.

⦁ Abrasion and Wear Resistance:

It enhances surface protection and durability, significantly increasing product longevity.

⦁ Sound, Heat, and Electrical Insulation:

Rubber powder offers excellent insulation, making it perfect for acoustic panels used in studios, theaters, and offices.

⦁ Anti-Slip Properties:

It adds non-slip features to surfaces, making it ideal for wet or humid areas, enhancing safety and comfort.

⦁ UV and Weather Resistance:

Certain types are UV- and weather-resistant, ensuring long-lasting performance in harsh environments.

⦁ Easy Integration:

It blends seamlessly with other materials, making it versatile for various applications.

⦁ Antibacterial Properties:

Some types possess antibacterial qualities, ideal for environments that require hygiene and cleanliness.

- For immediate service and fast logistics across Egypt, benefiting from Egypt’s strategic location connecting to all global markets.

Recyclable & Eco-Friendly

Made entirely from recycled materials to support sustainability and environmental responsibility.

Easy Maintenance

Engineered for simple cleaning and upkeep to maintain its appearance and high performance over time.

Sound Insulation

Effectively absorbs noise, creating a quiet and comfortable environment—ideal for gyms and indoor courts.

Cutting-Edge Technology

Produced using the latest manufacturing technologies for exceptional performance and minimal maintenance.

Safe Application

Provides a secure surface that minimizes slipping and reduces the risk of injuries.

Anti-Slip Surface

Designed with high friction resistance to ensure safe play even in wet or humid conditions.

Durability

Outstanding strength and wear resistance, capable of withstanding intensive use in any environment.

Specialized Solutions

We provide customized flooring systems tailored to your project’s unique needs and specifications.

Water Resistance

Developed to prevent water absorption and moisture buildup, keeping the surface permanently dry.

High Load Capacity

Engineered to bear heavy weights and pressure without deformation or damage.

Easy Installation

Offers exceptional stability with quick assembly, disassembly, and maintenance whenever needed.

International Standards

Manufactured according to the highest global quality and safety standards to guarantee unmatched performance.

Rubber Powder Mesh Size Chart (20 / 30 / 40 Mesh)

Rubber powder mesh size is usually the first thing to confirm before requesting a quote. Common grades we supply:

Typical direction: general industrial blends where a coarser powder is acceptable (spec dependent).

Buyer note: confirm process compatibility and target performance.

Typical direction: balanced option for many formulations (spec dependent).

Buyer note: good starting point if your spec allows flexibility.

Typical direction: finer powder for more uniform blending (spec dependent).

Buyer note: confirm mixing method and consistency requirements.

Custom mesh sizes are available on request—send your spec sheet or target requirement during inquiry.

Advanced Rubber Powder Manufacturing Process (Recycled SBR & Micronized) – From Tire to Controlled Mesh

At Sport Floor, our rubber powder manufacturing process is designed to deliver consistent grades of recycled SBR rubber powder and micronized rubber powder with controlled particle size (mesh) for industrial buyers. The goal is simple: stable quality, repeatable supply, and specifications that match your application.

- We start by collecting used tires and rubber waste from approved sources. The material is then sorted and cleaned to reduce variation between batches and to prepare it for further processing. Good sorting at this stage helps improve consistency in the final rubber powder.

- The tires are processed through shredding and crushing to produce rubber chips. This step makes it easier to remove non-rubber components and prepares the material for grinding.

To meet industrial requirements, non-rubber components are separated:

- Steel wires are removed using magnetic separation systems.

- Textile fibers are reduced/removed using airflow and screening systems (process dependent).

The output is a cleaner rubber feedstock, ready for powder production.

We use different grinding approaches depending on the target specification and application:

A) Mechanical Grinding

Mechanical grinding reduces rubber chips into smaller particles using industrial cutting/grinding systems. It is commonly used for producing standard grades where a controlled mesh size is required.

B) Cryogenic Grinding (for finer, more uniform requirements)

In cryogenic grinding, rubber is cooled to very low temperatures before milling. This process can help produce cleaner, more uniform particles for applications that require higher consistency—often relevant for coatings, adhesives, and precision blends (application dependent).

Why this matters for buyers: The grinding method affects surface texture, uniformity, and how the powder blends into your formulation.

After grinding, the material is classified to meet the required mesh size.

- Higher mesh = finer powder

- Lower mesh = coarser powder

We support common supply grades such as 20 / 30 / 40 mesh, plus custom specifications on request.

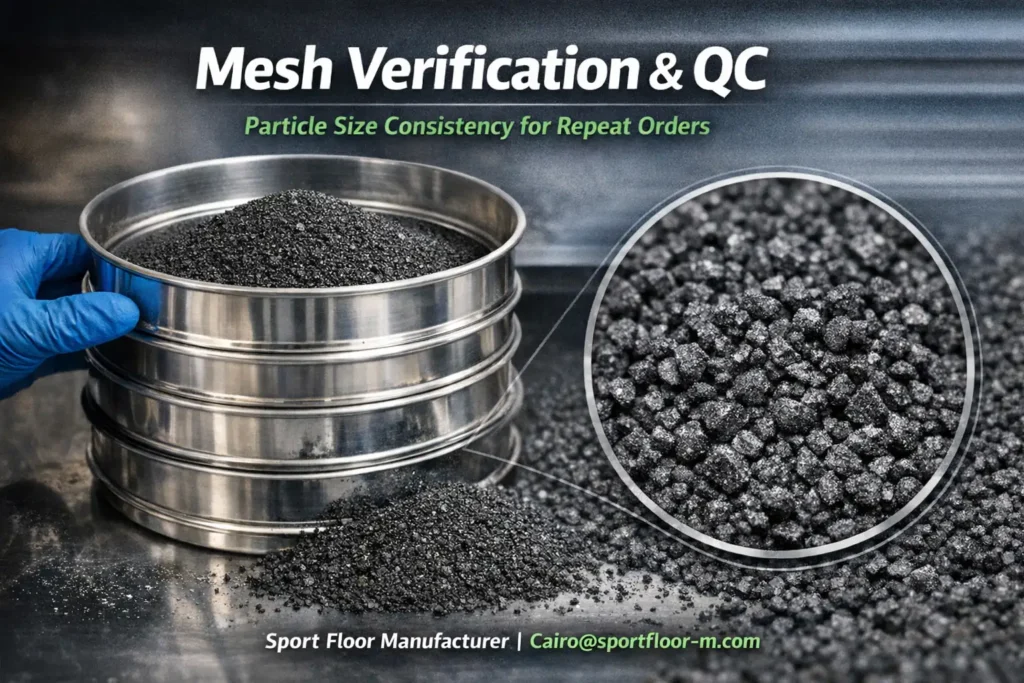

Before shipment, rubber powder is checked to confirm it matches the requested specification (scope dependent). Quality control focuses on the items industrial buyers care about most:

- Mesh size / particle size distribution (not just “one number”)

- Consistency across batches for repeat purchasing

- Contamination control (steel/textile residual control requirements, if specified)

- Moisture / handling readiness (especially important for certain applications and packing conditions)

Practical buyer note: Which mesh fits which use?

- Finer powders (higher mesh) → often used for more uniform blending (coatings/adhesives/formulations, spec dependent)

- Coarser powders (lower mesh) → often used for asphalt modification and filler-type applications (spec dependent)

If you share your application, we can recommend the most suitable rubber powder grade and confirm the best quotation scope.

Diverse Rubber Powder Applications — Our Innovative Solutions for the Future of Industries

Rubber powder has a wide range of applications across multiple industries, unlocking vast opportunities for sustainable growth. Its role goes far beyond being a cost-effective alternative to raw materials — it has become a key enabler of innovation, performance enhancement, and product efficiency.

At Sport Floor Rubber Flooring Factory, we provide comprehensive and customized solutions for every industrial need.

- Infrastructure and Construction: The Foundation of Strength and Sustainability

- Rubberized Asphalt (Modified Asphalt)

- Rubber Concrete

- Insulation Materials

- Other Building Materials

- Lightweight Filler Material

The infrastructure and construction sector is one of the main beneficiaries of rubber powder, as it contributes to building stronger, more durable, and eco-friendly structures.

One of the most important applications of rubber powder is in rubberized asphalt. Adding rubber powder to asphalt improves road durability, reduces cracking and wear, and minimizes tire-road noise. Studies have shown that rubber-modified asphalt can extend road life by up to 50% while reducing long-term maintenance and repair costs. It also enhances road safety thanks to its excellent skid resistance.

Incorporating rubber granules into concrete mixes increases flexibility, impact resistance, and sound absorption. Research indicates that higher rubber aggregate content lowers concrete density, reducing overall weight — ideal for lightweight concrete projects and seismic zones.

Rubber powder is effectively used in manufacturing sound and vibration insulation materials, making it an ideal solution for industrial and architectural applications to create quieter and more comfortable environments.

When added to brick and tile mixtures, rubber powder enhances properties such as thermal insulation, fire resistance, soundproofing, and slip resistance.

Rubber powder can be mixed with soil or used as lightweight aggregate in road and bridge construction, reducing structural loads and improving ground stability — especially in areas with weak soil conditions.

Important Note: Follow the supplier's thermal expansion instructions—for large spaces, leave expansion joints at the edges.

Sports and Recreation: World-Class Sports Flooring

Rubber powder is an essential component in creating safe and high-performance sports and recreational surfaces, which is our area of expertise at Sport Floor Rubber Flooring Factory.

⦁ Sports Surfaces:

Rubber powder is widely used in the production of sports surfaces such as running tracks, football fields, tennis courts, and golf courses. It provides a comfortable, safe, and shock-absorbing surface with excellent slip resistance, significantly reducing player injuries and enhancing play comfort.

⦁ Gym Floors and Weightlifting Areas:

Rubber-based flooring protects subfloors from heavy equipment impact and offers a flexible, cushioned surface that reduces joint stress — making it the preferred choice for gyms and fitness centers.

⦁ Children’s Playgrounds:

Used in parks, gardens, and playground areas to provide soft, slip-resistant, and safe flooring, ensuring maximum child safety.

The applications of rubber powder extend far beyond infrastructure and sports, covering a wide range of industries:

⦁ Automotive Industry:

Rubber powder is added to tire compounds to increase flexibility and wear resistance. It’s also used in automotive components such as seals, gaskets, and insulators, improving performance and reducing noise and vibration.

⦁ Adhesives:

Used in adhesive manufacturing to enhance cohesion strength and elasticity, resulting in more durable and flexible products.

⦁ Paints and Coatings:

Micronized rubber powder is used in coatings and paints. Chlorinated rubber powder (a white, odorless type) is employed in anticorrosive paints and coatings for its resistance to acids, alkalis, and excellent insulation properties. Studies show that adding rubber powder can increase coating durability by up to 30%.

⦁ Footwear Industry:

Rubber powder is used in outer soles, midsoles, and toe caps, offering durability, slip resistance, and comfort. Additives like carbon black and calcium carbonate are blended to enhance strength, durability, and cost efficiency.

⦁ Cables and Wires:

Rubber powder mixed with talc is used in rubber cables to strengthen the cable sheath and improve electrical insulation properties.

⦁ Agriculture and Soil Improvement:

When added to soil, rubber powder improves moisture retention and aeration, promoting plant growth and productivity while reducing soil erosion.

⦁ Tire-Derived Fuel (TDF):

Rubber powder is used as an alternative fuel in cement kilns, pulp and paper mills, and power plants, reducing carbon emissions and conserving non-renewable resources.

Micronized rubber powder is typically selected when your formulation needs a very fine rubber additive with improved uniformity and blending behavior compared to standard mesh grades. Common examples (application dependent): polymers, coatings, adhesives, and precision compounds.

Micronized vs Standard Mesh (Quick Buyer Comparison)

Standard rubber powder (mesh): best for many general industrial blending applications.

Micronized rubber powder: better fit when you need higher uniformity and performance-focused blending.

To avoid mismatched quotations, write “micronized rubber powder” explicitly in your request if you need it.

Superior Quality

Design Flexibility

Eco-Friendly Materials

Outstanding Technical Support

Recycled SBR Rubber Powder (Export Supply)

We supply recycled SBR rubber powder for buyers who need a cost-effective and sustainability-oriented input material (application dependent).

The correct grade depends on your process and local specification.

We take pride in being the largest tire recycling and rubber powder manufacturer and exporter in the region. This leadership is more than a title; it reflects our massive production capacity, advanced technologies, and extensive distribution network that spans the globe. Our operational scale ensures product availability in large quantities with consistent quality, meeting the demands of even the most challenging projects.

FIFA Quality & FIFA Quality Pro Certificates

International Sports Federations Approvals

Global ISO Certifications

European Standards (EN)

Common Rubber Powder Sizes

Maximize the benefits of your projects by choosing high-quality rubber powder from Sport Floor. Contact us today!

⦁ Particle Size: ~2 mm

⦁ Characteristics: Relatively coarse particles, suitable for applications requiring high mechanical resistance.

⦁ Applications:

⦁ Filling flooring layers in sports fields (e.g., artificial fields).

⦁ Soil improvement in road and dam projects.

⦁ Manufacturing construction materials such as rubber blocks.

⦁ Advantages:

⦁ High compression resistance.

⦁ Reduces cracking in concrete materials.

⦁ Particle Size: ~0.85 mm

⦁ Characteristics: Medium-fine particles, balancing durability and viscosity.

⦁ Applications:

⦁ Mixing with asphalt to improve road performance (Asphalt Rubber).

⦁ Manufacturing flexible surfaces for children (e.g., school playgrounds).

⦁ Filling rubber products such as rubber edges.

⦁ Advantages:

⦁ Uniform distribution in composite materials.

⦁ Improves flexibility of blended materials.

⦁ Particle Size: ~0.6 mm

⦁ Characteristics: Relatively fine particles, suitable for precise blends.

⦁ Applications:

⦁ Recycled rubber production (Rubber Compounding).

⦁ Manufacturing sports and flexible shoes.

⦁ Applications in plastic and rubber industries.

⦁ Advantages:

⦁ High homogeneity in blends.

⦁ Improves sound and thermal insulation properties.

⦁ Particle Size: ~0.425 mm

⦁ Characteristics: Very fine powder-like particles.

⦁ Applications:

⦁ Mixing with polymers for advanced rubber materials.

⦁ Manufacturing new tires (as a complementary material).

⦁ 3D printing applications using rubber.

⦁ Advantages:

⦁ Easy dissolution and integration with other materials.

⦁ Enhances flexibility and smoothness.

The rubber powder market is experiencing steady growth both globally and in the Arab region, driven by increasing applications and growing environmental awareness. At Sport Floor, we closely monitor these developments to ensure we meet the evolving needs of the market.

Globally Certified Quality, Unwavering Commitment

- Quality is the cornerstone of everything we do. At Sport Floor, we adhere to the highest international quality standards, ensuring our customers receive products that exceed their expectations.

- Our factory is certified with ISO 9001:2015, and approved by international sports federations such as IAAF (International Association of Athletics Federations) and ITF (International Tennis Federation). These certifications are more than documents; they are proof of our strict commitment to quality and safety at every stage of production.

We implement strict quality control procedures at all stages of production, from selecting the raw materials (impurity-free recycled tires) to the final product. Comprehensive testing is conducted to analyze particle size, purity, and physical and chemical properties to ensure that our rubber powder meets the requirements of various industries and delivers the expected performance.

We guarantee our products’ purity of up to 99.99%, ensuring optimal performance in sensitive applications.

Tailored Solutions & Strategic Partnerships: Comprehensive Support for Your Projects

We understand that every project is unique, which is why we provide customized solutions tailored to your exact needs:

- ⦁ We can produce rubber powder in various particle sizes, colors, and specifications to meet your specific requirements.

- ⦁ Thanks to our partnerships with reliable shipping companies and our modern fleet of vehicles, we ensure safe and timely delivery anywhere in the world.

⦁ Our expert team provides technical support and specialized consulting to help you choose the right products for your projects and achieve optimal results.

At Sport Floor, sustainability is not just a slogan; it is an integral part of our operational identity:

⦁ Waste Reduction: Tire recycling reduces the amount of rubber waste sent to landfills, helping to protect the environment.

⦁ Conservation of Natural Resources: Using recycled rubber granules reduces the need for virgin raw materials, preserving natural resources.

⦁ Circular Economy: We actively contribute to the circular economy by turning waste into valuable resources, creating jobs and stimulating local economic growth.

⦁ We understand the importance of cost-efficiency in your projects. Our rubber powder is offered at highly competitive prices, making it a more economical choice compared to new raw materials. This not only reduces initial costs but also ensures excellent long-term ROI due to the durability and long lifespan of our products.

Don’t compromise on quality or sustainability. Choose Sport Floor for premium rubber powder. Contact our sales team today!

Request a Rubber Powder Quotation (Fast Checklist)

Copy/paste and send this checklist for the fastest quotation:

- Recycled SBR rubber powder / Micronized rubber powder

- 20 mesh / 30 mesh / 40 mesh / custom spec

Modified asphalt / coatings / rubber compounds / other

total tons + order frequency (one-time or repeat supply)

bags / big bags / pallet preference (if required)

country + nearest seaport

EXW / FOB / CIF

Send via contact form: contact us

Email: cairo@sportfloor-m.com

Official Incoterms reference (for buyers): incoterms rules

| Indicator | Value (Million USD) |

|---|---|

| Total Exports | 1 |

| Total Imports | 94 |

| Trade Balance Deficit | -93 |

For export orders, packing method and shipment plan affect handling, container efficiency, and the final delivered cost.

Before comparing suppliers, confirm: mesh size + packaging + total tons + destination port + Incoterms.

EXW: buyer manages pickup and export logistics from origin.

FOB: supplier delivers to loading port (scope must be confirmed).

CIF: quote includes cost/insurance/freight to destination port (port is required).

Commitment to quality and international standards represents a critical competitive advantage in this market. Obtaining certifications such as ISO 9001:2015 and approvals from international sports federations (IAAF, ITF) is not merely a requirement, but a trust-building factor that opens doors to global markets and major projects. This ensures that customers receive products that meet performance and safety expectations, enhancing sales and increasing market share.

Rubber powder, or rubber granules, is a versatile material produced from recycling used rubber tires and other rubber waste. It is processed into fine granules or powder through advanced grinding and refining methods.

Rubber powder is used in modified asphalt, rubber compounds, coatings, and engineered mixes. The correct mesh size depends on your application and specification.

The production process starts with collecting, sorting, and cleaning used tires. They are then shredded into small pieces, and non-rubber components such as steel wires and textile fibers are removed. The pure rubber pieces are ground using advanced techniques like mechanical grinding or cryogenic grinding (liquid nitrogen) to produce granules and powders of different sizes.

Micronized rubber powder is an ultra-fine rubber powder used when higher uniformity and improved blending are required (application dependent). Mention “micronized” clearly in your inquiry.

Yes, rubber powder is highly eco-friendly. It is made from recycled tires, significantly reducing waste sent to landfills, conserving natural resources, and lowering harmful emissions.

We are the tire recycling and rubber powder production and export facility in the region. We combine extensive experience (over 30 years), advanced technology, globally certified quality, competitive pricing, sustainability commitment, customized solutions, and full technical support for our clients.

Yes, we have an excellent track record exporting our high-quality products worldwide. We work with reliable shipping companies and follow international standards to ensure safe and timely delivery.

Common grades include 20 / 30 / 40 mesh, and we can support custom specifications on request depending on scope and volume.

Yes, you can contact us to request samples to evaluate quality and specifications before placing a bulk order.

You can contact us via the “Contact Us” page, specifying the required quantities, specifications, and the name of the shipping port.

They are related, but buyers usually distinguish them by particle size. “Rubber powder” often refers to finer mesh grades, while “crumb rubber” can also refer to larger granules depending on the market.

Yes. Share destination port and preferred Incoterms (EXW/FOB/CIF) and we will quote accordingly.

we are a global supplier of rubber powder.

Need rubber powder for export or bulk supply?

Send your mesh size (20/30/40 or custom), quantity (tons), and

destination port to receive a complete quotation and shipping scope confirmation.

Contact: contact us

Email: cairo@sportfloor-m.com