Tartan Materials — Components for PU Sports Surfacing (Spec-based Supply)

Sport Floor Manufacturer supplies tartan materials for polyurethane sports surfaces where procurement requires system clarity (primer/base/top and any elastic layers).

To quote correctly, we align materials with the intended system type, total area, and site conditions (project-dependent).

Tartan materials are purchased as a system set rather than standalone items—because performance depends on layer compatibility and correct coverage planning. For fast quoting, share the sport type, total m², and target system (or ask us to recommend a system).

- PU court resurfacing projects (site-dependent)

- New court construction requiring full layer supply

- Running track projects needing system-matched materials

Materials, Systems & Buyer Articles

- Back to category: Tartan Courts (Hub)

- System selection: Tartan Systems (recommended before ordering materials)

- Running track page: PU Running Track

- Buyer articles: Running Track Systems · PU Athletic Track · PU Sports Flooring

- Proof before purchase: Our Projects

Quote Checklist + Incoterms (Tartan Materials)

- Project type: court / running track

- Total area: m²

- Target system: (or request recommendation)

- Color preference:

- Quantity unit: kg / sets (system-based)

- Destination + Incoterms: EXW / FOB / CIF

Official Incoterms reference (ICC): incoterms rules

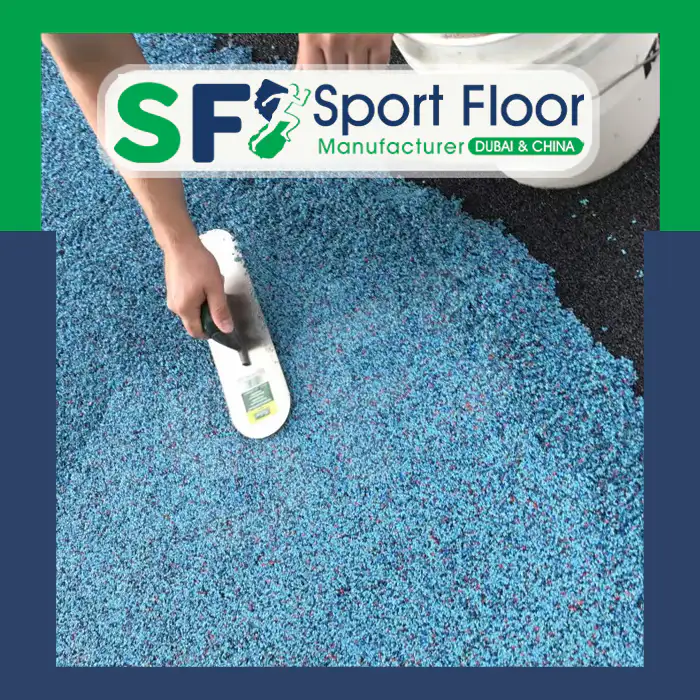

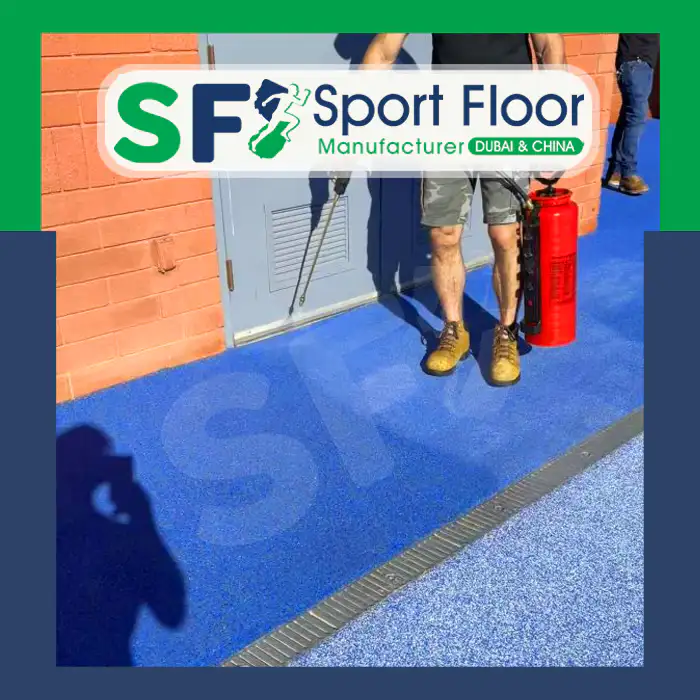

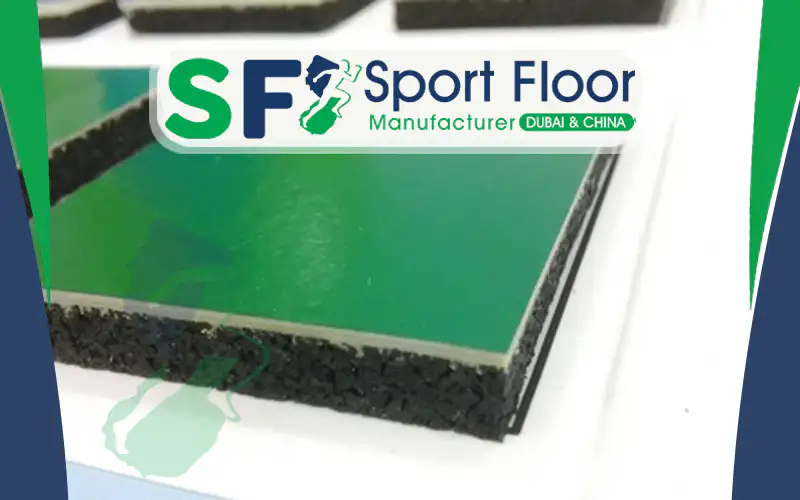

The core Polyurethane (Tartan Materials) Raw Materials consist of Polyurethane (PU) resins as the main binding agent, combined with EPDM or SBR granules as the infill and surface layer. In addition, the system includes primers, leveling compounds, UV-resistant additives, and flexible foam or cushion layers to ensure optimal elasticity. The selection and ratio of each material directly determine the surface’s durability, shock absorption, and color stability, delivering consistent high performance under all climatic conditions.

When planning or purchasing a Tartan system (for tracks, courts, or multipurpose areas), understanding the materials is the foundation of making the right technical and commercial decision. At Sport Floor, our experts provide you with a full overview of all Polyurethane (Tartan) Raw Materials actually used in professional systems — detailing the function of each component, its practical specifications, and its impact on performance and environmental safety. This comprehensive approach ensures your project delivers reliable performance and long-lasting durability from day one.

| Material | Description & Function | Main Properties | Expected Use |

|---|---|---|---|

| PU (Polyurethane) | Main binder for sports surface layers. | High strength, adequate working time. | Surface layer, base layers. |

| Aliphatic PU | UV-resistant PU type that retains color. | Long-term color stability. | Topcoat layer. |

| Aromatic PU | Cheaper but fades quickly under sunlight. | Lower cost. | Internal layers. |

| EPDM | Colored synthetic rubber resistant to weather. | Stable colors, UV resistant. | Top surface layer. |

| SBR | Recycled rubber from car tires. | Economical but less durable. | Cushion layer. |

| TPE / TPV | Alternative to SBR/EPDM. | High performance, higher cost. | Special surface alternatives. |

| Silica Sand | Filling and shock absorption adjustment. | Improves bonding and adds weight. | Infill material. |

| Adhesive Primers | For bonding PU layers to concrete or asphalt. | Improves adhesion. | Priming layer. |

| Leveling Compounds | Used for surface leveling. | Creates an even surface before coating. | Preparation layer. |

| Fleece / Geotextiles | Separation layer between materials. | Protects against cracks. | Underlayment layer. |

| Additives | Auxiliary materials such as UV stabilizers. | UV resistance, anti-fungal properties. | Mixed within compound. |

| Water-based PU | Eco-friendly paint type. | Low VOC emissions. | Internal and final coatings. |

| Adhesives & Tapes | Used for bonding joints. | High adhesion strength. | Line installation. |

| Foam / Elastic Layer | Shock-absorbing sponge layers. | Comfort and flexibility. | Cushion layer. |

Technical Details and Practical Specifications from the Sport Floor Manufacturing Lab

Tartan Materials

Common sizes range from 0.5–3.0 mm (depending on the system).

Typical bulk density is around 1.2 g/cm³.

Available colors include red, blue, green, and speckled black — designed to maintain long-term color stability and UV resistance.

Most commonly available in 0.5–4 mm sizes, typically in black color.

The recycled content percentage is always clearly specified to ensure traceability and sustainability.

The ratio varies based on design requirements.

A typical top-layer example includes 12–25% PU resin (by weight) mixed with 88–75% EPDM granules through industrial blending.

(These are representative values — the exact ratios depend on the specific Tartan system design.)

Ideal ambient temperature: 10–30°C, with low humidity during application.

The pot life of the two-component resin typically ranges from 20 to 60 minutes, depending on formulation and temperature.

System Thickness

⦁ Light-duty systems: 6–8 mm

⦁ High-performance running tracks and courts: 25–30 mm

This variation allows customization for performance, comfort, and impact absorption.

Recyclable & Eco-Friendly

Made entirely from recycled materials to support sustainability and environmental responsibility.

Easy Maintenance

Engineered for simple cleaning and upkeep to maintain its appearance and high performance over time.

Sound Insulation

Effectively absorbs noise, creating a quiet and comfortable environment—ideal for gyms and indoor courts.

Cutting-Edge Technology

Produced using the latest manufacturing technologies for exceptional performance and minimal maintenance.

Safe Application

Provides a secure surface that minimizes slipping and reduces the risk of injuries.

Anti-Slip Surface

Designed with high friction resistance to ensure safe play even in wet or humid conditions.

Durability

Outstanding strength and wear resistance, capable of withstanding intensive use in any environment.

Specialized Solutions

We provide customized flooring systems tailored to your project’s unique needs and specifications.

Water Resistance

Developed to prevent water absorption and moisture buildup, keeping the surface permanently dry.

High Load Capacity

Engineered to bear heavy weights and pressure without deformation or damage.

Easy Installation

Offers exceptional stability with quick assembly, disassembly, and maintenance whenever needed.

International Standards

Manufactured according to the highest global quality and safety standards to guarantee unmatched performance.

Polyurethane (Tartan) Raw Materials Approved by Sport Floor Experts

Tartan Materials

- ⦁ Define Function and Use: Competitive track? Kids’ playground? Multi-purpose hall? Each determines the Cushion thickness and type of granules.

⦁ Climate Conditions: For sunny regions, choose EPDM surface + Aliphatic PU. For high-temperature areas, use heat-stability tested systems.

⦁ Environmental Considerations: If your requirements include Low-VOC or avoiding crumb rubber, select TPE or certified PFAS-free EPDM.

⦁ Budget and TCO: Recycled SBR provides a lower initial cost, while EPDM offers longer color life and durability — calculate total cost over 5–10 years.

⦁ Certifications and Reports: Sport Floor products are certified with MSDS, VOC, PTV/EN, and all factories hold ISO certification.

- ⦁ VOC Emissions: Lab reports from Sport Floor (VOC test) are available for indoor projects.

⦁ Crumb Rubber Concerns: Concerns exist regarding tire-derived granules — Sport Floor offers safer EPDM alternatives.

⦁ Recyclability: Check the percentage of recycled content (verified according to your project specifications by Sport Floor).

⦁ Safe Additives: Avoid materials containing phthalates or substances classified as hazardous.

Storage, Handling, and Purchasing Requirements from Sport Floor Factory

Tartan Materials

At Sport Floor, we adhere to the highest quality standards at every stage of production and supply.

We recommend storing the two-component PU material within the temperature range specified by the manufacturer, completely away from moisture and water, to ensure chemical stability and consistent on-site performance.

EPDM/SBR granules should be kept in dry, shaded areas protected from direct sunlight to maintain elasticity, color stability, and long-term quality.

All our products come with detailed Shelf-life and Pot-life data for the resins, ensuring full transparency of technical specifications before installation and guaranteeing optimal performance during application.

Sport Floor factory always provides free samples of raw materials — such as EPDM granules and PU mixtures — after contract confirmation.

This allows our clients to conduct PTV (Slip Resistance) and Shock Absorption tests before installation, ensuring compliance with international standards for sports fields and facilities.

Sport Floor factories proudly hold a wide range of international certifications and test reports that confirm the superior quality of their products.

These certifications include:

• ISO Certificates for quality and management systems.

• Third-Party Laboratory Test Reports from accredited organizations.

• MSDS (Material Safety Data Sheets) and complete Product Data Sheets for every item.

• Verified project references for installations completed across Europe, the Middle East, and Africa.

At Sport Floor, quality is not just a promise — it is a documented commitment, backed by certifications and test results that guarantee confidence both before purchase and after installation.

Core Quality Tests Certified by Sport Floor

At Sport Floor, we are committed to delivering flooring systems that exceed European EN and international ASTM standards in performance, durability, and sustainability.

- PTV / Pendulum Test – Slip Resistance

- Shock Absorption – EN 14808

- Color Stability – UV Resistance

- Indoor Emissions – VOC Test

- Tensile Strength & Elongation

- Adhesion Tests

Our products are certified through the Pendulum Test (PTV), measuring the Slip Resistance Value in accordance with British and European standards.

This ensures that every Sport Floor surface delivers maximum safety, even in wet or high-traffic conditions—ideal for sports fields, walkways, and public areas.

Sport Floor systems have successfully passed the EN 14808 Shock Absorption Test, verifying an optimal balance between flexibility, support, and player protection against sports-related injuries.

We use advanced UV resistance testing technologies to guarantee color fastness and prevent fading even after years of exposure to intense outdoor sunlight and heavy usage.

For indoor flooring applications, we perform strict VOC Emission Tests to ensure that all our materials are eco-friendly, non-toxic, and free from harmful emissions, maintaining a safe and healthy environment.

Resin samples are meticulously tested to confirm excellent tensile strength and ideal elongation rates, reflecting the purity and chemical stability of our Polyurethane (Tartan) Raw Materials.

We place strong emphasis on adhesion performance between:

• Primer and concrete,

• Resin and rubber granules.

These tests guarantee a fully integrated flooring system that resists peeling, delamination, and environmental stress even under the harshest weather conditions.

| Reason for Selection | Recommended Option | Application |

|---|---|---|

| Color stability, UV resistance, World Athletics specifications | PU + EPDM (pour-in-place) | Athletics track / running track |

| Balanced cost and safety | PU + SBR cushion + EPDM top | School or club courts |

| High shock absorption | EPDM + Cushion | Children’s play areas |

| Compression resistance and easy tile replacement | EPDM or rebonded SBR coated tiles | Weight rooms / fitness centers |

| Recycled content and improved environmental safety | EPDM or low-VOC TPE/TPV | Eco-friendly solutions |

Sport Floor — Global Leader in Certified Sports Flooring Solutions

At Sport Floor, we provide fully integrated sports flooring solutions with top industrial quality, precisely manufactured in our advanced factories in China and Dubai, and supported by comprehensive logistics from our Cairo branch, ensuring full coverage of the Middle East, Africa, and worldwide markets — all at competitive prices.

With extensive experience in 47 countries around the world, we guarantee long-lasting, high-performance, and cost-efficient products.

We offer a complete system that includes:

⦁ Manufacturing of internationally certified products

⦁ Direct factory supply, saving you over 40%

⦁ Professional shipping and delivery to any destination

All within a production philosophy that ensures safe performance, lasting durability, and low operational costs over the long term.

Sport Floor — Industrial Expertise and Certified Quality Serving the World from 47 Countries.

Superior Quality

Design Flexibility

Eco-Friendly Materials

Outstanding Technical Support

Global Trust in Quality and Performance

Sport Floor proudly owns a wide network of clients across different continents, becoming a trusted name in the sports flooring and certified Polyurethane (Tartan) Raw Materials industry.

From Asia to Europe, America, Africa, and the Middle East, our partners share real success stories that reflect our commitment to quality and international standards.

🏅 Sport Floor – Global Expertise with Local Trust

With branches in China, Dubai, and Cairo, and logistical partnerships in more than 47 countries, Sport Floor continues to support sports projects with the highest quality standards, offering certified solutions that compete globally in performance, durability, and operational cost-efficiency.

⦁ Importing Polyurethane (Tartan) Raw Materials to build a 900-meter running track with 5 lanes — the result was excellent, and the track was officially approved.

Amateur Club (USA)

⦁ We used to import from the United States, but since 2005, we have become loyal Sport Floor clients for all sports flooring systems, especially Tartan tracks.

Sports Contracting Company (Russia)

⦁ Since the establishment of our company 15 years ago, specialized in sports flooring, we have been importing our materials from Sport Floor branches, and we are proud of this partnership.

General Contracting Company (China)

FIFA Quality & FIFA Quality Pro Certificates

International Sports Federations Approvals

Global ISO Certifications

European Standards (EN)

The essentials: Polyurethane (PU) resins as the binder, EPDM or SBR granules as fillers, primers for adhesion, and leveling or cushioning layers (foam or rebond). Additionally, UV stabilizers and safety-enhancing additives are used.

EPDM: UV-stable colored granules suitable for top layers and sunlight exposure.

SBR: Recycled black rubber, cost-effective, commonly used as a cushion core for shock absorption.

Two main types: Aromatic PU (less expensive, ideal for indoor use) and Aliphatic PU (UV-resistant, perfect for outdoor top coats with long-term color stability).

Yes — TPE/TPV, low-emission EPDM blends, and plant-based or recycled granules are proven environmentally friendly options.

Typically between 0.5 mm and 4.0 mm, depending on the surface system and texture required.

Depending on design, a common example for surface layers: 15–25% PU resin (by weight) to 75–85% granules. These ratios are indicative — always refer to the official Data Sheet.

Systems range from 6–8 mm for light applications up to 20–30 mm for running tracks and heavy-duty fields requiring high cushioning.

Pot life is the working time after mixing PU components. It is affected by temperature and humidity — exceeding it may cause poor bonding or premature curing.

Typically between 10–30°C with low humidity. Cold or humid conditions may extend drying times and affect adhesion.

VOC emission reports (for indoor use), UV color stability tests, PTV slip resistance tests, and EN 14808 shock absorption tests.

SBR is widely used, but in some markets it raises concerns due to potential contaminants in recycled raw material. EPDM is a safer alternative.

Request UV-treated EPDM and apply a PU top coat for extended color life.

Store PU in a cool, dry area away from moisture; store EPDM/SBR away from direct sunlight and humidity. Always check shelf-life dates.

It varies by product; PU resins typically last from several months up to a year in proper conditions; granules last longer but should be inspected for smell and texture before use.

Yes — you can request EPDM/SBR and PU mix samples for testing (PTV, adhesion, and VOC) after contracting and before execution.

It reduces cost and improves sustainability but may require quality control to maintain mechanical and environmental consistency.

Yes — flame retardants and antifungal agents can be added for specific applications, provided they meet local standards.

Yes — EPDM top surfaces are easier to clean and maintain than black SBR, and the base layer choice determines repair and replacement ease.

Depends on pot life and site temperature; installation can start immediately after preparation, respecting primer and layer curing times.

Yes — many Tartan systems are partially recyclable, but it requires material separation and cooperation with specialized recycling facilities.

Sport Floor provides every export shipment with MSDS, Data Sheets, Certificate of Origin, and Packing List.

A materials and systems engineer specializing in tartan sports fields with 18+ years of experience, who has supervised the design and implementation of tartan sports field projects in Europe, Asia and the Middle East, and is an expert in performance and safety specifications.

M. Zhang Ming Manager of the Tartan Flooring Department at Sport Floor