PU Sports Flooring Manufacturer (2026): Complete Guide to Indoor & Outdoor PU Court Systems

If you’re searching for PU sports flooring for a school, sports club, academy, gym, or multi‑use facility, you’re likely comparing different surface options and trying to answer one key question: Which system will perform well, last long, and stay cost‑effective after daily use?

Polyurethane sports flooring is popular because it can be engineered for athlete comfort, reliable traction, and consistent performance, while also offering practical maintenance—especially when the correct sub‑base preparation and system specification are followed.

At Sport Floor Manufacturer, we supply polyurethane sports flooring systems for indoor and outdoor sports courts and multi‑purpose facilities. This page explains how PU sports flooring works, the system options available, what specifications matter most, and what information you should send to receive an accurate quotation.

If your facility includes athletics tracks too, you can also review:

- PU athletic track manufacturer

- Running track systems (Full PU vs Sandwich vs Spray)

Quick Quote (Fast Response)

To receive pricing and the correct system recommendation, send:

- Country/city (or destination port for CIF)

- Indoor or outdoor

- Sports to be played (basketball/volleyball/badminton/multi‑sport)

- Court dimensions or total area (m²)

- Sub‑base type (concrete/asphalt) and current condition

- Color(s) and line marking requirements

- Incoterms (EXW/FOB/CIF) + timeline

Then request pricing through our technical team (recommended starting point):

Tartan materials

What Is PU Sports Flooring?

PU sports flooring (polyurethane sports flooring) is a multi‑layer synthetic surface system typically installed over a properly prepared sub‑base (often concrete or asphalt, depending on the project). PU systems can be designed for different sports and different performance needs, including:

- Slip resistance and controlled traction

- Shock absorption and athlete comfort

- Durability under frequent use

- Stable appearance and easier cleaning compared with some alternatives

In practice, PU is chosen when facility owners want a surface that supports consistent play, feels comfortable, and remains maintainable over years of use—especially in schools, clubs, and commercial sports facilities.

Where PU Sports Flooring Performs Best (Common Applications)

PU court surfaces are widely used because they fit multiple facility types and different sports requirements.

Indoor PU Sports Flooring

Indoor courts often prioritize:

- predictable ball response (depending on sport)

- controlled slip resistance

- comfort during long play sessions

- easy cleaning and a clean “professional” look

Common indoor applications:

- Basketball courts

- Volleyball courts

- Badminton courts

- School sports halls and academies

- Multi‑purpose indoor gym floors (when specified correctly)

Outdoor PU Court Surface

Outdoor surfaces must handle:

- UV exposure

- heat and temperature movement

- rain and moisture management

- dust and frequent cleaning

Common outdoor applications:

- Multi‑purpose courts (basketball/volleyball/handball)

- School yards and community courts

- Club outdoor training areas

If your project includes surrounding rubber areas or playground surfacing, you may also need EPDM materials:

PU Sports Flooring System Options We Deliver (Choose the Right System)

One reason buyers struggle with PU flooring procurement is that “PU sports flooring” is not a single product—there are multiple system builds.

Below are common PU court system types used in sports facilities. The best option depends on indoor/outdoor conditions, expected traffic, and comfort level required.

1) Smooth PU Sports Flooring (General Purpose)

Best for:

- facilities that need a clean, simple court finish

- multi‑use courts where comfort is important but heavy cushioning is not the main goal

Key benefits:

- smooth professional appearance

- easier day‑to‑day cleaning

- cost‑effective for many school and club applications

2) Textured / Slip‑Resistant PU Court Surface

Best for:

- courts that require controlled traction, especially in outdoor or high‑humidity use

- multi‑sport facilities where players need stable grip

Key benefits:

- improved traction control

- better confidence for fast direction changes

- helps reduce slip risks when properly specified

3) Cushioned PU Sports Flooring (Comfort‑Focused)

Best for:

- higher comfort needs

- long training sessions

- facilities that want a more “athlete‑friendly” feel

Key benefits:

- improved comfort and impact feel

- supports repetitive training use

- can be specified to match facility needs

Quick Comparison Table (Buyer-Friendly)

PU Sports Flooring Systems — Comparison

- Smooth PU: best for general-purpose indoor courts, clean finish, practical budgets

- Textured PU: best for controlled traction, outdoor use, and multi-sport stability

- Cushioned PU: best for comfort-focused training and premium indoor facilities

If you are unsure, we recommend selecting the system after confirming:

- indoor/outdoor conditions

- base type and condition

- sports played and usage intensity

Technical Specifications That Actually Matter (2026 Buyer Checklist)

When buyers compare suppliers, the biggest problem is comparing “general descriptions” instead of specifications. Here are the specs that matter most for performance and long-term results:

1) System Thickness and Layer Design

Thickness is not just a number—it’s part of system performance. The correct thickness depends on:

- usage level (school vs club vs commercial)

- comfort expectations

- sub‑base quality

A responsible supplier will recommend the thickness range based on your real conditions, not a one-size-fits-all number.

2) Slip Resistance and Surface Texture

Good PU sports flooring should provide controlled traction. Too slippery becomes unsafe; too rough becomes uncomfortable and can increase wear.

Always specify:

- indoor vs outdoor traction requirements

- whether the court is likely to face moisture or dust

- the sport type (fast turns vs controlled movement)

3) UV and Weather Resistance (Outdoor PU Courts)

For outdoor PU court surfaces, ask specifically about:

- UV stability and color performance

- system suitability for hot climates

- surface behavior under temperature changes

4) Line Marking Quality (Multi‑Sport Courts)

For multi‑purpose court flooring, line marking is part of the “usable product.” Good line marking means:

- accurate layouts

- long-lasting marking under use and cleaning

- clear separation between sports (colors and standards)

5) Drainage and Water Management (Outdoor Facilities)

PU flooring systems rely on correct base preparation and slope planning for outdoor sites.

If the base is wrong, the surface will suffer—no matter how good the top layer is.

Sub‑Base Requirements (This Is Where Most Projects Fail)

Most sports flooring problems come from base preparation. If you want a surface that lasts, treat the sub‑base as a critical part of the system.

Sub‑Base Checklist (Short and Practical)

Before you approve installation:

- What is the base? Concrete or asphalt

- Is the base flat and within tolerance?

- Are cracks treated and controlled?

- Is the base dry and ready (moisture control)?

- For outdoor: is slope/drainage designed correctly?

- Are expansion joints handled correctly (if applicable)?

- Are electrical routes planned (lighting, accessories)?

If your project is a full athletics facility, review the track requirements too:

Indoor vs Outdoor PU Sports Flooring (How the Specification Changes)

Many suppliers use the same marketing text for indoor and outdoor systems. In reality, they are not the same.

Indoor Considerations

- comfort and controlled grip

- lower UV exposure concerns

- more consistent temperature

- focus on easy cleaning and stable performance

Outdoor Considerations

- UV resistance and heat tolerance

- dust and frequent washing

- rain exposure and drainage

- surface texture to support safe movement

If you tell us your city and whether it’s a coastal/high-humidity area, we can recommend the suitable surface texture and system build.

PU Sports Flooring for Multi‑Purpose Courts (How to Plan Layouts)

Multi‑purpose courts are common in schools, clubs, and community projects. The mistake many buyers make is choosing a surface without planning line marking and usage.

What to define before quoting

- sports to be included (basketball, volleyball, badminton, handball, futsal, etc.)

- priority sport (which sport’s layout is dominant)

- line colors for each sport

- buffer zones and safety margins

A clear layout plan reduces:

- redesign costs

- marking disputes

- long-term confusion for facility users

Quality Control, Documentation & Compliance (Proof Matters)

For professional procurement, you need more than claims. You need documentation and traceability.

What we can support

- TDS (Technical Data Sheets) and SDS (Safety Data Sheets) available upon request for key materials

- material identification and packaging clarity for export projects

- installation guidance and system recommendations based on application

For a full overview of materials used across sports surfaces, see:

If your facility includes rubber surfacing areas, you can also source:

Export & Delivery Terms (EXW / FOB / CIF) + How to Quote International Projects

Sport Floor Manufacturer supports international procurement with export-ready supply planning. To avoid misunderstandings, always confirm your Incoterms:

- EXW (Ex‑Works): pickup from agreed supply point

- FOB: delivery to export port and loading (as agreed)

- CIF: freight to your destination port (recommended for budgeting)

What we need to quote correctly

- destination country + city (or port for CIF)

- quantity (m² scope or project package scope)

- system type (smooth/textured/cushioned, indoor/outdoor)

- timeline and site readiness

Proof: Projects / References (Add Real Installations Here)

This section is extremely important for both ranking and conversion. Add:

- 6–12 real project photos (wide + close-up)

- short captions: country/city + court type + year

- optional: client type (school/club/hotel) if allowed

Even without naming clients, showing real installations improves trust and conversion.

Get Pricing & System Recommendation (Fast Quote Block)

If you want the fastest, most accurate quotation for PU sports flooring, send:

- Country/city (or destination port for CIF)

- Indoor or outdoor

- Sport(s) played + expected daily usage

- Total area (m²) or court count

- Base type and status (concrete/asphalt, ready/not ready)

- Color(s) + line marking requirements

- Incoterms (EXW/FOB/CIF) + target delivery date

For a facility that includes tracks and courts, it’s often best to quote the full package together:

EPDM vs SBR Rubber Granules

| Property | EPDM | SBR |

|---|---|---|

| UV Resistance | Excellent | Limited |

| Color Stability | High | Low |

| Cost | Higher | Lower |

| Typical Use | Top layer | Shock layer |

📌 Professional systems use both materials together to balance performance and cost.

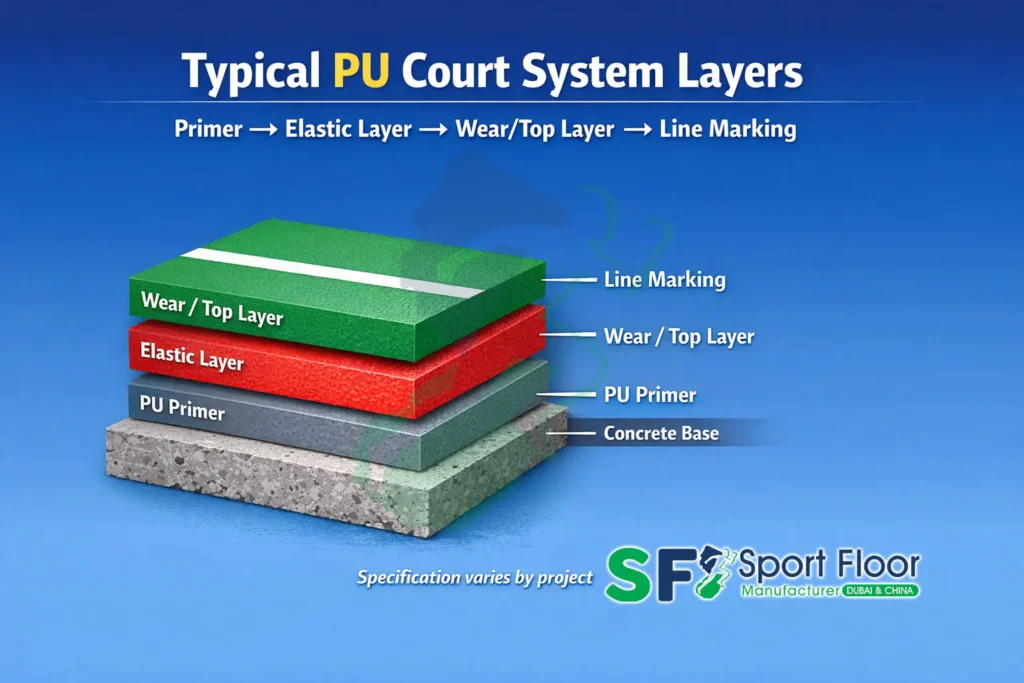

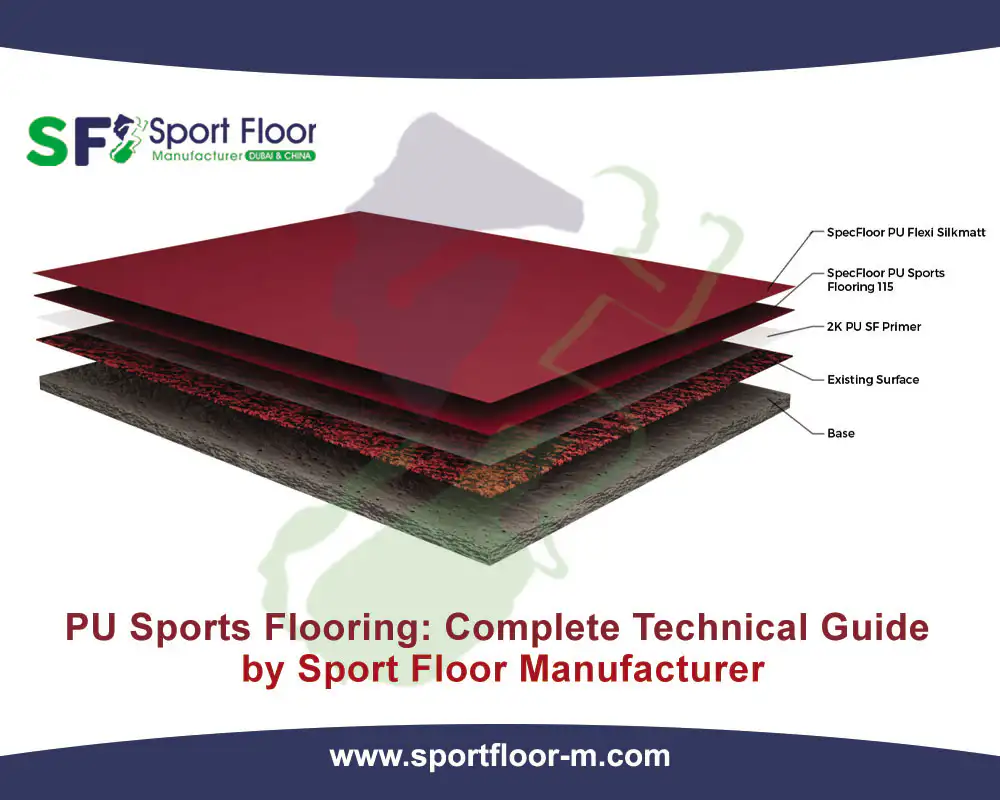

Installation Overview

A standard PU sports flooring installation includes:

Base inspection and repair

Primer application

Elastic shock absorption layer

Leveling layer (if required)

EPDM wearing course

Line marking

📌 Installation must be carried out by trained professionals using certified materials.

Maintenance and Service Life

PU sports flooring requires minimal maintenance:

Regular cleaning

Annual inspection

Minor repairs if needed

With proper maintenance, systems can last over a decade without performance loss.

Why Choose Sport floor Manufacturer?

At Sport floor-M, we are not only suppliers — we are manufacturers of PU sports flooring raw materials and systems.

We provide:

✔ High-quality PU binders and resins

✔ EPDM & SBR rubber granules

✔ Custom system designs

✔ Technical support for contractors

✔ Global supply capabilities

Our systems are designed to meet international standards and real-world performance demands.

Built by a Manufacturer, Trusted by Athletes

PU Sports Flooring for running tracks is the modern industry standard when you demand consistent performance, athlete safety, and long-term value.

At Sport Floor Manufacturer we design, formulate, and install full PU track systems that combine energy return, shock absorption, and weather resistance to meet training and competition needs. This page explains exactly what PU Sports Flooring delivers, how our systems are engineered, and why facility managers, municipalities, and stadium owners choose us as their technical partner.

Compliance & Certification — We Speak the Standards Language

Sport Floor Manufacturer supplies systems that can be tested and submitted for World Athletics (formerly IAAF) product certification when required by the client. Certification confirms that a given product, when installed to the specified absolute thickness and in compliance with installation protocols, meets the technical requirements for competition surfaces. We assist clients from sample testing through documentation and factory technical support to facilitate the certification process.

Why this matters: certification is often a contractual or funding requirement for stadiums, public-sector projects, and elite competition venues. As a manufacturer, we control formulation and supply so we can support the laboratory testing and reference sampling that certifiers require.

Real-World Solutions — Which PU System Fits Your Project?

We classify PU Sports Flooring systems by use case. Below are simplified categories to help you select the right solution quickly:

To understand the best construction method for your site, see our guide to running track systems (Full PU vs Sandwich vs Spray)

Community & school tracks

Typical thickness: 10–12 mm sandwich / porous top courses.

Focus: durability, cost-efficiency, and reduced maintenance.

Benefits: long service life with minimal upkeep, suitable for multi-purpose community use.

Athletic club & municipal tracks

Typical thickness: 12–15 mm multilayer systems.

Focus: balance of performance and lifecycle cost.

Benefits: improved energy return for training athletes, serviceable for regional competitions.

Competition grade & elite stadiums

Typical thickness: 15 mm and up; World Athletics–grade top-course options.

Focus: strict performance specs, certification, and long-term color/texture stability.

Benefits: suitable for sanctioned events, precise biomechanical characteristics for elite athletes.

Installation — Manufacturer-Controlled Process

As a manufacturer and installer, Sport Floor Manufacturer executes every step to guarantee system performance:

Substrate assessment & preparation — crack repair, primer, and profile to ensure consistent bonding.

Base binder application — poured or spray-applied polyurethane binder cured to specification.

Intermediate layers & embedding — foam layer (if specified) and precise EPDM embedding for top-course.

Top-course finishing — levelling, texture control, and final resin sealing.

Marking & QA testing — we run post-installation performance checks to validate shock absorption, vertical deformation, and surface hardness as required.

Proper installation is critical — even high-grade PU Sports Flooring will underperform if substrate and bonding are not expertly managed. We provide technical supervision and installation teams trained on manufacturer best practices to eliminate common installation failure modes.

Maintenance & Lifecycle Planning

Routine maintenance is straightforward and cost-effective:

Regular sweeping and pressure washing to remove grit and debris.

Line re-marking every 3–7 years depending on wear and usage intensity.

Localized repairs for point damage using patch kits rather than full replacement.

Periodic performance audits to plan surface refreshes before end-of-life.

Planned maintenance extends service life and preserves warranty conditions. Higher-quality PU Sports Flooring systems typically require only periodic minor works rather than wholesale resurfacing.

Sustainability & Material Choices

We offer PU Sports Flooring formulations with recycled-content options for EPDM granules and binders reduced in volatile organic compounds (VOCs). Choosing a sustainable PU system reduces embodied carbon over the life cycle and supports municipal sustainability targets without compromising technical performance. We can provide material declarations and lifecycle impact summaries during project planning.

Pricing Guide & Value

Project costs for PU Sports Flooring vary by system type, thickness, site substrate condition, and local logistics. Typical budget ranges (indicative):

Basic community system (10–12 mm): budget-conscious option for schools and parks.

Mid-tier club/municipal system (12–15 mm): balanced performance and durability.

Competition-grade system (15+ mm, World Athletics compliant): premium materials, testing, and documentation.

Because we manufacture the binder and coordinate logistics, we deliver competitive pricing and predictable lead times. For accurate budgeting we provide free site assessments and line-item proposals that split material, installation, testing, and warranty into transparent components.

Comparison: PU Sports Flooring vs Other Track Surfaces

PU vs. Rubberized loose-laid systems: PU is fully bonded, offering superior long-term stability and lower infiltration of debris; loose-laid systems are cheaper initially but may require earlier renewal.

PU vs. Asphalt/painted tracks: PU offers engineered shock absorption and athlete feedback; painted asphalt lacks consistent performance and wears faster.

PU vs. hybrid EPDM/latex systems: High-quality PU systems outperform in UV and spike resistance while hybrid systems can be more economical but less durable under heavy competition use.

designed to meet World Athletics requirements

Case Studies & Proven Projects

As a manufacturer, Sport Floor Manufacturer has completed projects for municipal parks, university athletic centers, and private stadiums.

Our typical deliverables include material certificates, installation QA records,

and post-installation test results that clients can use for funding and certification approvals.

Contact us for anonymous case studies and reference contacts in your region.

Common Buyer Mistakes (And How to Avoid Them)

Mistake 1: Choosing a system without checking the base

Result: cracks, debonding, uneven performance, early repairs.

Fix: confirm base flatness, moisture readiness, and outdoor drainage.

Mistake 2: Buying “indoor” specs for an outdoor court

Result: faster fading, surface issues under heat and weather.

Fix: specify outdoor requirements clearly (UV, texture, drainage planning).

Mistake 3: No clear line marking plan

Result: confusion, rework costs, and disputes after installation.

Fix: define sports and line colors before quoting.

Mistake 4: Comparing quotes with different scopes

Result: “cheapest” offer excludes key items.

Fix: compare the same scope: system type, thickness approach, markings, base scope, and Incoterms.

FAQ — PU Sports Flooring Manufacturer

1) What is PU sports flooring used for?

PU sports flooring is used for indoor and outdoor courts and multi‑sport facilities where controlled traction, comfort, and durability are required—commonly in schools, clubs, academies, and community courts.

2) Which PU system is best: smooth, textured, or cushioned?

It depends on indoor/outdoor conditions, sports played, and comfort requirements. If you are unsure, share your project details and we will recommend the most suitable system.

3) Can PU sports flooring be used outdoors?

Yes, when the system is specified for outdoor conditions (UV exposure, heat, moisture, drainage). Outdoor success depends heavily on proper base and slope planning.

4) Do you provide documentation?

TDS and SDS are available upon request for key materials. Additional documents depend on market requirements and project scope.

5) Do you export PU sports flooring materials internationally?

Yes. We support export planning based on Incoterms (EXW/FOB/CIF). Send your destination port and project scope to receive the correct quotation.

6) Can you support full sports facility projects (tracks + courts)?

Yes. Many buyers combine court flooring with running track projects. You can review:

7) What information do you need to quote quickly?

Country/city (or port), indoor/outdoor, sports, area, base type/status, color and line marking requirements, Incoterms (EXW/FOB/CIF), and target timeline.

Conclusion

The best PU sports flooring is not just a “surface”—it is a complete system built on a properly prepared base, with the right texture, performance goals, and layout planning. If you want a court that performs well and stays cost‑effective after daily use, start with the correct specification.

Send your project details (location, indoor/outdoor, sports, area, base status, colors, and Incoterms) and we’ll recommend the right PU system and provide a clear quotation.

Related pages you may need:

Request Pricing (PU Sports Flooring) — Get a Quote

To receive accurate EXW/FOB/CIF pricing for your PU sports flooring project, send us your details (country/city or destination port, indoor/outdoor, total area in m², sport type(s), sub‑base status, colors/line marking, and target timeline). Our technical team will recommend the right system and reply with a clear quotation, lead time, and shipping options.

Contact Our Technical Sales Team

📧 Cairo: Cairo@sportfloor-m.com

📧 China: China@sportfloor-m.com

🔗 Request Form: Contact Us – Sport Floor Manufacturer