Running Track Systems (2026): Full PU vs Sandwich vs Spray Coat — Choose the Right System and Get a Quote

A Technical Guide by Sport floor Manufacture

Building an athletics facility starts with one key decision: choosing the right running track system for real conditions—not just for a brochure. The best system is the one that matches your usage level, climate, sub‑base quality, and budget, while delivering safe performance and long service life.

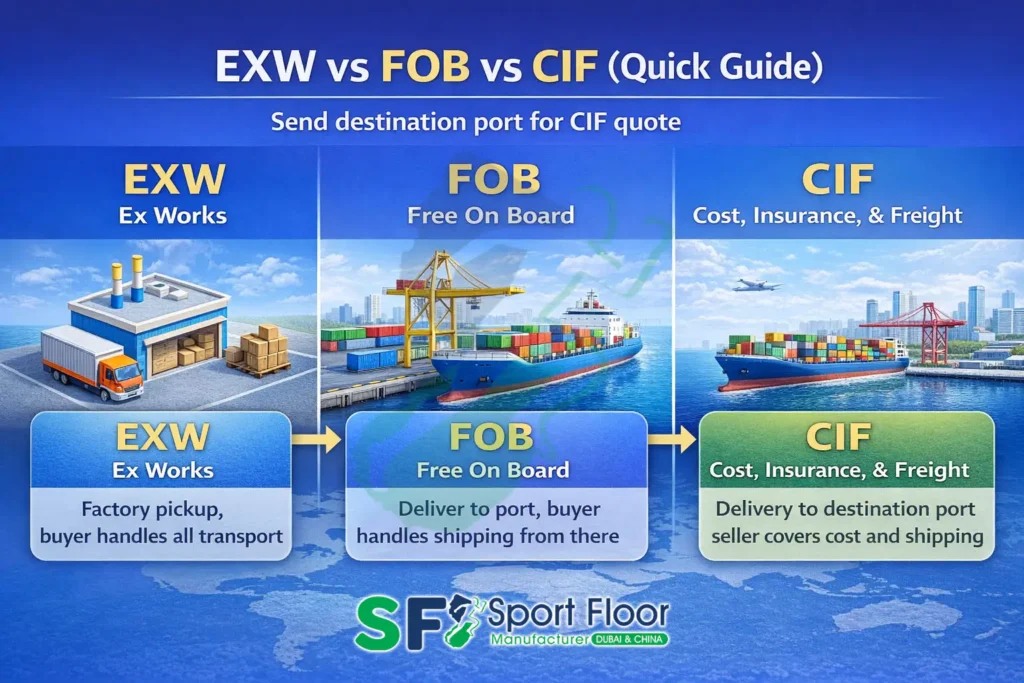

At Sport Floor Manufacturer, we support buyers and contractors with system selection, track materials supply, export planning (EXW/FOB/CIF), and turnkey running track installation support for international projects. Our solutions are designed to meet World Athletics (formerly IAAF) requirements depending on the project specification, installation method, and any required testing.

Quick links (start here):

- Tartan Running Track (complete solution)

- PU Athletic Track Manufacturer (manufacturer page)

- Tartan Materials (materials overview)

Request Pricing or Ask for a System Recommendation

Request a Quote (EXW/FOB/CIF)

Ask for System Recommendation

Contact Our Technical Sales Team

Cairo

China

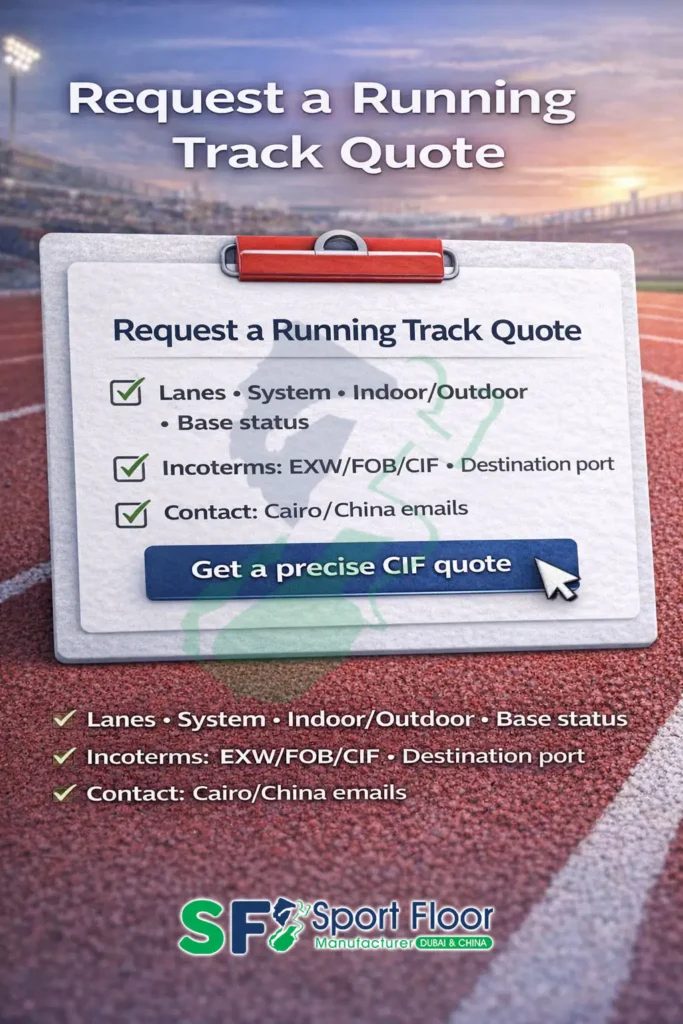

Fast Quote Checklist (Send This and Get a Clear Offer)

To receive the fastest and most accurate recommendation + quotation for your running track systems, please send:

- Country / City (or destination port for CIF)

- Number of lanes + track layout (if available)

- System preference (Full PU / Sandwich / Spray Coat)

- Indoor or Outdoor

- Sub‑base type and status (asphalt/concrete, ready/not ready)

- Expected usage (school / club / stadium)

- Incoterms (EXW / FOB / CIF)

- WhatsApp / Email

- Target timeline

Send your details here

What you will receive from us:

- Recommended system (Full PU / Sandwich / Spray) + suggested thickness approach

- Confirmation of key base requirements and scope

- Lead time and production/export plan

- EXW/FOB/CIF quotation structure (aligned with your Incoterms)

- Packing & shipping plan for export projects (when requested)

Why Global Buyers Choose Sport Floor Manufacturer

When you are sourcing a running track system internationally, the lowest price is rarely the lowest risk. Buyers choose us because we focus on technical clarity, consistent supply, and export readiness.

- Export experience: our products are supplied to 47 countries, including UAE, USA, China, India, Argentina, Brazil, Uruguay, and Egypt (and more).

- Manufacturer perspective: we support projects with materials, system selection, and documentation—not generic “one offer fits all.”

- Procurement clarity: we quote clearly based on your scope and Incoterms (EXW/FOB/CIF) to avoid cost surprises.

- System selection support: we help you choose Full PU vs Sandwich vs Spray based on usage, climate, and base readiness.

- Documentation support: TDS/SDS available upon request for professional procurement.

- Full facility support: if your site includes courts and rubber areas, we can supply additional materials and solutions (see links later).

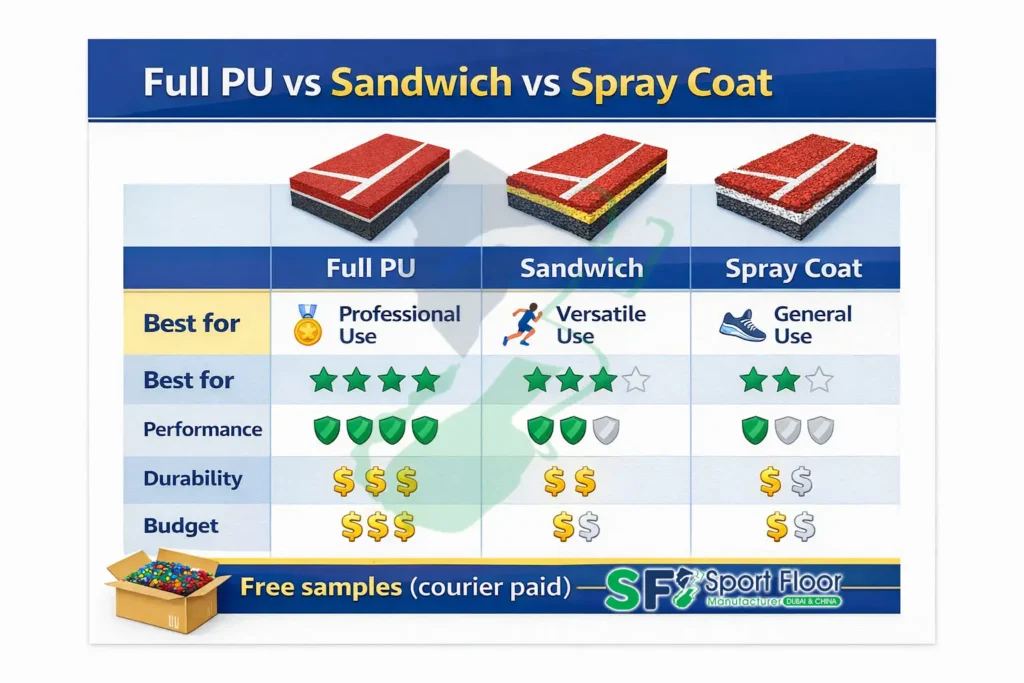

Quick Comparison: Full PU vs Sandwich vs Spray Coat Running Track Systems

Use this comparison to narrow down your choice quickly, then read the system details below.

Full PU running track system

Best for: stadiums, high-performance training, heavy daily use

Strengths: premium durability and consistent performance

Risk if chosen incorrectly: higher cost without real benefit; needs excellent sub‑base tolerance

Sandwich running track system

Best for: clubs, schools, universities, multi‑sport facilities

Strengths: strongest cost‑to‑performance ratio, robust wear resistance

Risk if chosen incorrectly: performance issues if drainage/flatness is weak

Spray coat running track system

Best for: entry budgets, training facilities, controlled usage

Strengths: cost‑effective when matched correctly

Risk if chosen incorrectly: faster wear if used for heavy commercial booking

Not sure which system fits your budget and usage?

Send your details and we’ll recommend the best specification for your site, climate, and traffic level:

contact us

For a deeper technical breakdown, see:

Running Track Systems Manufacturer (Full PU vs Sandwich vs Spray)

Running Track Systems Explained (What You’re Actually Buying)

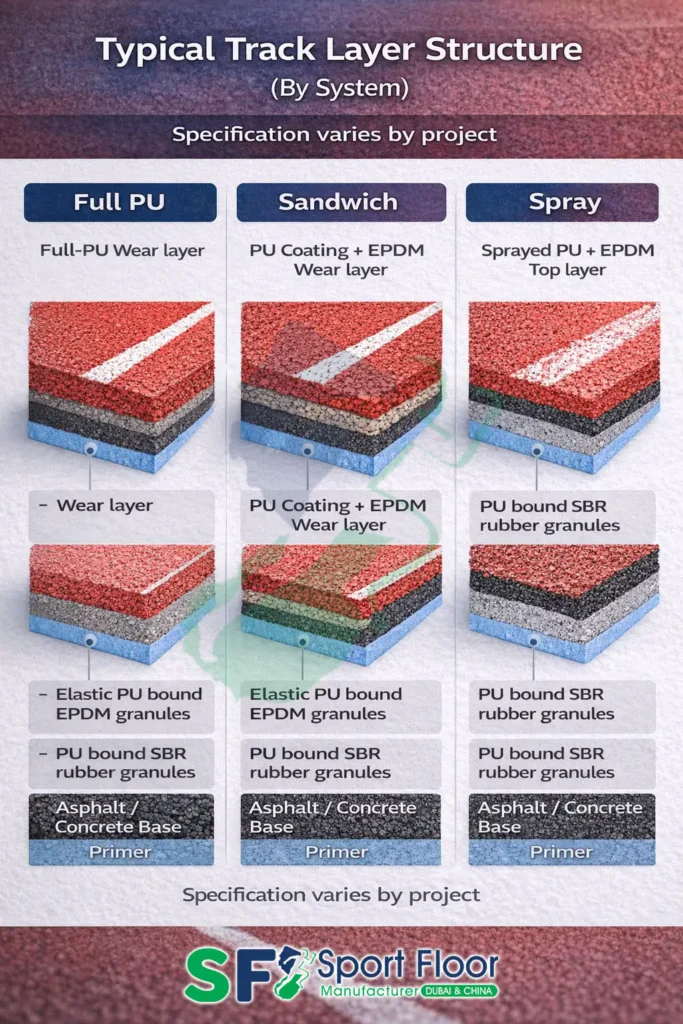

A “tartan” or “PU” running track is not a single product. It’s a layered performance system installed over a properly prepared base. Most systems include:

- Primer (bonding layer)

- Elastic/base layer (shock absorption and comfort)

- Wear/top layer (texture, durability, slip control)

- Line marking (lane layout, starts, and competition markings)

Different running track systems mainly differ in how the elastic layer and top finish are constructed and specified.

Materials and components reference:

Tartan Materials

System 1: Full PU Running Track (High Performance & Heavy Use)

What is a Full PU running track?

A Full PU running track is a fully polyurethane-based system typically selected for high-performance facilities and heavy usage. It is chosen when consistent behavior, premium durability, and refined finish options matter most.

Best-fit projects

- Stadiums and advanced athletics facilities

- High-traffic clubs and academies

- Professional training environments

- Projects designed to meet World Athletics requirements (depending on specification and site execution)

Key advantages for buyers

- Uniform performance and consistent feel underfoot

- Strong long-term durability when installed correctly

- Premium finish and stable surface behavior across lanes

- Professional appearance for competitive facilities

Common buying mistakes to avoid

- Selecting a premium system while the sub‑base is not within tolerance

- Ignoring drainage planning for outdoor tracks

- Comparing offers without confirming scope (materials, layers, markings, base readiness)

If you want factory-direct support and turnkey planning, start here:

PU Athletic Track Manufacturer

System 2: Sandwich Running Track (Most Popular Value Option)

What is a Sandwich running track?

A Sandwich running track is one of the most widely selected systems because it delivers strong performance with excellent cost control. For many buyers, it’s the best “safe decision” for schools and clubs where durability matters and budgets must remain practical.

Best-fit projects

- Schools and universities

- Sports clubs with daily usage

- Multi‑sport facilities needing durability and manageable maintenance

Key advantages for buyers

- Excellent cost-to-performance ratio

- Strong wear resistance in real daily use

- Practical maintenance and stable appearance

- A reliable choice for long-term facility operation

Common buying mistakes to avoid

- Underestimating base flatness and moisture readiness

- Choosing the system without confirming usage intensity (traffic level)

- Not aligning lane marking scope and layout before quoting

System 3: Spray Coat Running Track (Budget-Friendly When Correctly Matched)

What is a Spray coat running track?

A Spray coat running track is a cost-focused system where the finish is spray-applied. It can be a good solution when facility usage is moderate and expectations are realistic.

Best-fit projects

- Entry-level school facilities

- Training areas with controlled traffic

- Projects with limited budgets where heavy commercial booking is not the goal

Key warning (important for buyers)

Spray coat is not automatically “bad”—but it becomes problematic when used for heavy commercial booking all day. If usage will be high, Sandwich or Full PU usually provides better long-term value.

How to Choose the Right Running Track System (Decision Checklist)

1) Usage intensity (your main decision driver)

Ask: how many hours per day will the track be used?

- Light/moderate use → Spray coat may be enough

- Medium/high use → Sandwich is often the best value

- Very high use / premium goals → Full PU is often preferred

2) Indoor vs Outdoor environment

Outdoor tracks must handle:

- UV exposure and heat

- Rain and water management

- Dust and frequent cleaning

- Drainage planning (base slope matters)

Indoor tracks typically focus on:

- Consistent traction and comfort

- Stable environmental conditions

- Controlled maintenance conditions

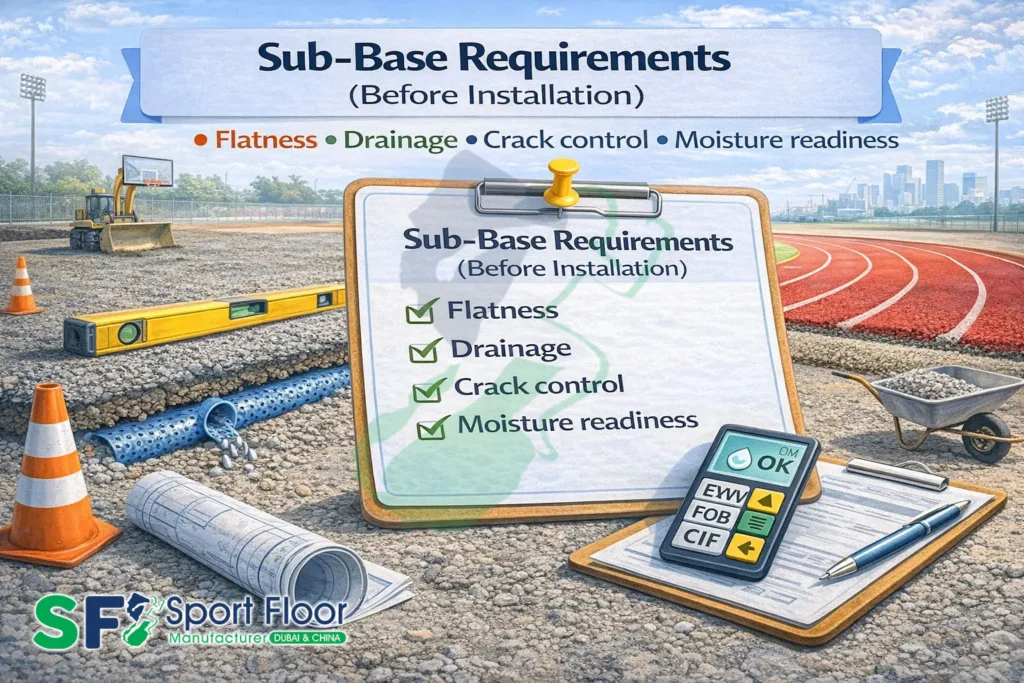

3) Sub‑base readiness

Most failures start from base issues, not from surface materials. Confirm:

- Flatness tolerance

- Crack control and stability

- Moisture readiness

- Slope/drainage for outdoor sites

4) Budget vs lifecycle cost

A “cheaper” system can become more expensive later if it:

- Wears too fast

- Needs frequent repairs

- Causes downtime and user complaints

There is no universal “best” system—only the most appropriate system for a specific project.

Performance Comparison (Buyer-Friendly)

Feature | Full PU | Sandwich | Spray

- Shock absorption: Excellent | Very Good | Good

- Slip resistance (when specified correctly): Good | Excellent | Excellent

- Durability: Very High | High | Medium (usage dependent)

- Cost level: High | Medium | Lower

- Installation speed (site ready): Medium | Medium | Fast

Designed to Meet World Athletics (IAAF) — Accurate Explanation

Many buyers search for “IAAF standard running track.” Today, the correct reference is World Athletics (formerly IAAF).

A professional supplier should explain it accurately:

- Track systems can be designed to meet World Athletics requirements depending on the project specification and installation method.

- Official certification typically depends on the full installed system, site execution, and any required testing.

If your project is tender-based or needs specific compliance documentation, send your requirements and we will confirm scope:

contact-us

Base Requirements (Most Common Reason Tracks Fail)

Regardless of system type, base quality is critical. Minimum base requirements include:

- Asphalt or concrete base (as specified by project design)

- Flatness within specified tolerances

- Correct drainage slope (outdoor tracks)

- Treated cracks and expansion joints

- Proper curing and moisture readiness before PU application

Many track failures originate from poor base preparation, not surface materials.

For turnkey planning and full solutions:

Tartan Running Track

Materials Checklist (What a Professional Quote Should Include)

To compare offers fairly, ensure the quotation clearly confirms:

- Primer

- Elastic/base layer materials

- Wear/top layer materials

- Line marking paint and layout scope

- Optional finishing layers (if specified)

- Installation guidance and documentation (where applicable)

Materials reference:

Tartan Materials

Projects/References

Related Facility Solutions (Tracks + Courts + Rubber Areas)

Many sports projects include multiple zones (tracks, courts, playground areas). If your facility is multi-purpose, these pages help you plan a complete package:

- PU Sports Flooring Manufacturer (courts)

- EPDM Granules Supplier & Manufacturer

- EPDM Granules Sizes Guide

- EPDM Granules Price per Ton (EXW/FOB/CIF)

Export & Delivery Terms (EXW / FOB / CIF) — For International Buyers

To avoid confusion and scope mismatch, always confirm the Incoterm used in the quote:

- EXW: price at supply point

- FOB: delivered to export port + loading (as agreed)

- CIF: freight to destination port (recommended for budgeting)

If you need CIF pricing, always provide your destination port and timeline.

Request your export quotation here : contact us

Request a Quote (CTA)

Request a Quote (EXW/FOB/CIF)

Ask for System Recommendation

Contact Our Technical Sales Team

Cairo: Cairo@sportfloor-m.com

China: China@sportfloor-m.com

FAQ — Running Track Systems (Commercial Buyer Questions)

1) Which running track system is best for schools?

For many schools and universities, the sandwich running track provides the best balance of durability and budget. Final selection depends on usage intensity and base readiness.

2) Is Full PU always better than Sandwich?

Not always. Full PU is excellent for high-performance and very heavy use, but sandwich systems often deliver the best long-term value for mainstream projects when specified correctly.

3) Is Spray coat suitable for commercial clubs?

Spray coat can be suitable for controlled usage. For heavy daily commercial booking, sandwich or full PU typically provides stronger long-term performance.

4) What do you need to quote CIF pricing accurately?

Destination port + lane count + system type + scope (materials only or turnkey) + timeline.

5) Do you provide turnkey support or only materials?

We support factory-direct materials, technical documentation, and execution planning. Scope depends on location and project requirements. Start here:

PU Athletic Track Manufacturer

6) How long does a running track system last?

Service life depends on system selection, installation quality, usage intensity, and maintenance. The best way to protect lifecycle value is choosing the correct system for your real usage and building on a properly prepared base.

7) Can old tracks be resurfaced?

Often yes—after technical evaluation of the existing base and system condition.

Conclusion

Choosing the correct running track system—Full PU, Sandwich, or Spray coat—should be based on real project conditions, not marketing claims. The right selection reduces maintenance risk, improves athlete experience, and protects your long-term investment.

To receive a recommended specification and an accurate EXW/FOB/CIF quotation, contact our team here: contact us